Fatigue Analysis: ASME Section VIII, Division 2, Part 5.5 Protection Against Failure from Cyclic Loading

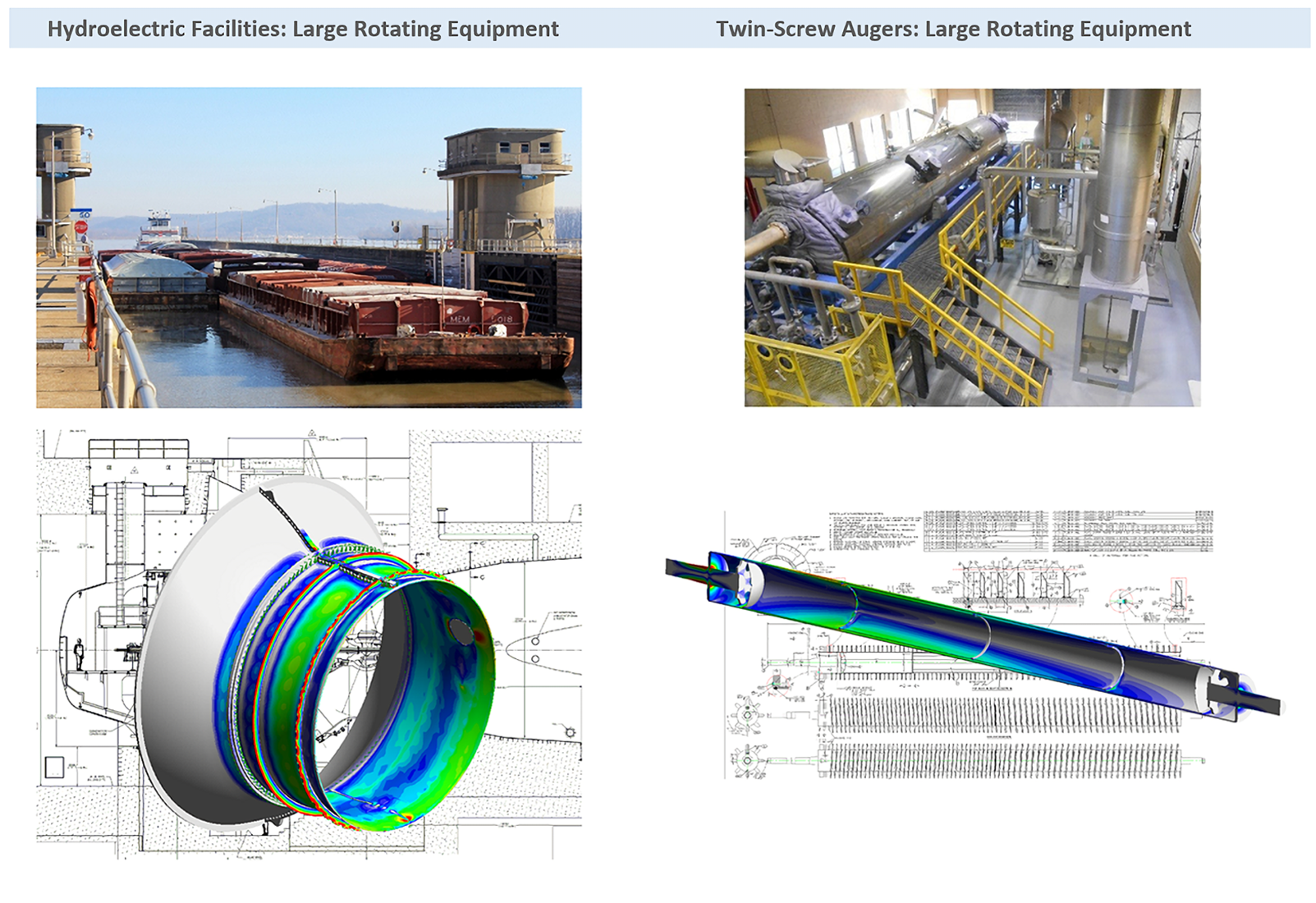

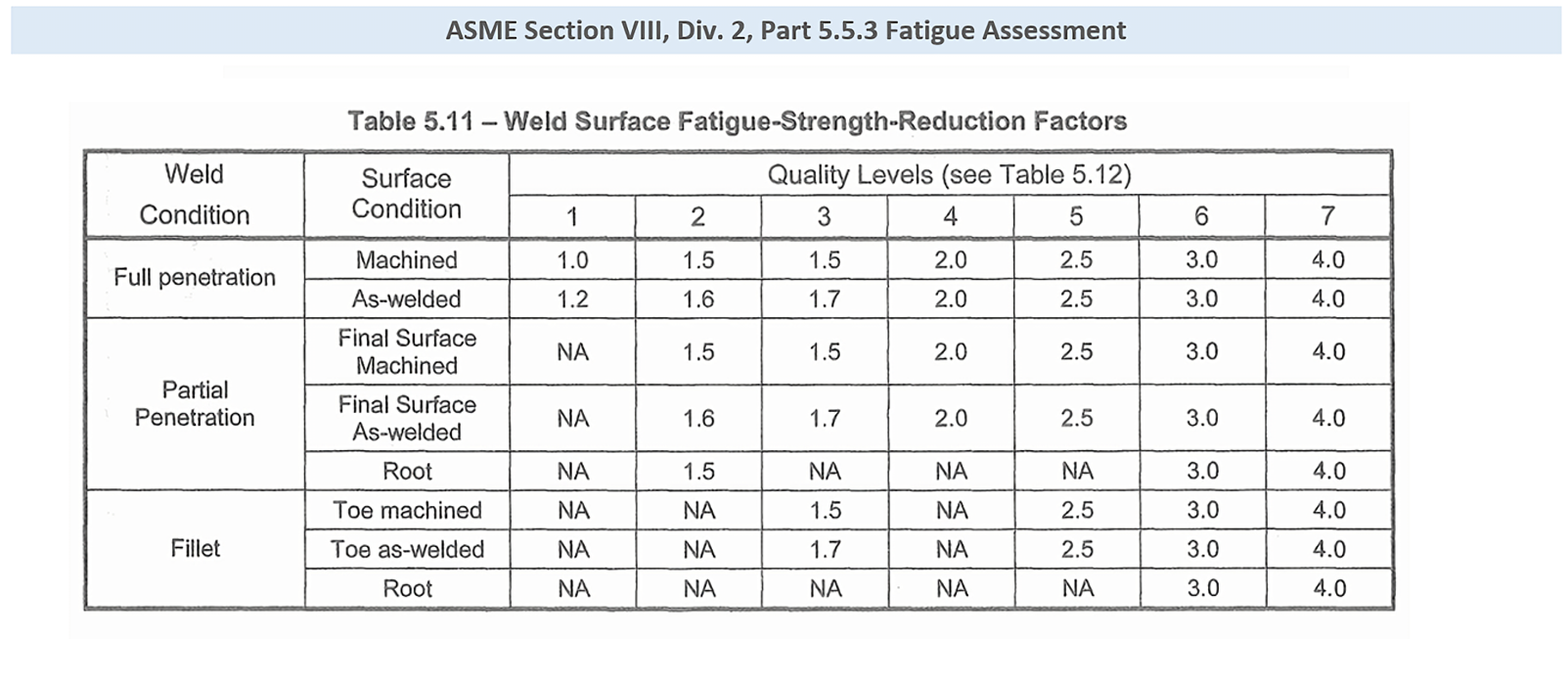

Even with an academic and experimental background in fatigue analysis, it is daunting to provide a hard, no-nonsense life-cycle prediction. It becomes especially daunting when your fatigue prediction can cost or save your client millions of dollars. Plus, there are tons of computer programs that promise “instant fatigue nirvana” at the press of a button; which leads one to ask: “What is a poor engineer supposed to do?” Over the years, we have learned that there are three critical components to a quality fatigue analysis: i.) accurate FEA stress results, ii.) accurate FEA stress results and iii.) accurate FEA stress results. Okay, sad, old, real-estate joke about location, location, and location; but let us just imagine that your stress numbers are good, then what? Fatigue analysis is all about the protection of structures and systems against failure from cyclic loading. This is where the ASME Boiler & Pressure Vessel Code (BPVC) provides a tried and true standard that, if your stress numbers are good, then you can be assured that your fatigue prediction will be conservative. Besides providing robust fatigue curves, the Code provides explicit guidance on how to treat welds based on type, inspection and surface quality. For example, if the weld is completely un-inspected and un-finished, then it earns a fatigue-strength-reduction factor or 4x, which means your FEA stress numbers are multiplied by 4x prior to the calculation of fatigue cycles per the ASME curve. In contrast, if a full penetration weld is ground to smooth profile and then fully-inspected (volumetric and surface examinations) , then the fatigue-strength-reduction factor is 1x. The ASME code makes clear that it is not saying that the weld material is as good as the base material, but merely that the ASME fatigue curves are still accurate. The ASME fatigue method was recently used to confirm cyclic fatigue damage and to guide subsequent design revisions. From an engineer’s perspective, it was a very satisfying journey since the Code provided clear guidance on how to treat welded and non-welded sections. The projects have been completed and now we wait to see what happens. Nothing is perfect and one never truly knows with fatigue, but at least following the ASME “Protection Against Failure from Cyclic Loading” we are not flying alone.