HVAC Applications

Analysis

Objective

At Predictive Engineering, we developed our expertise in computational fluid dynamics (CFD) consulting with years of CFD project work in medical, aerospace, marine, HVAC, civil (e.g., gas turbine power plants) and automotive. Our work has been extensively benchmarked by experiments and in-service testing, giving us the necessary validation experience for world-class CFD service to our clients.

Our portfolio of case studies provides hard evidence of our many successful CFD consulting projects.These consulting endeavors include space-based communications equipment, hydroelectric spillways and HVAC air handling systems, to name just a few. We feel that our broad experience brings a fresh perspective to our clients’ CFD challenges. This experience provides a cross-pollination between industries that have shared physics but different structures.

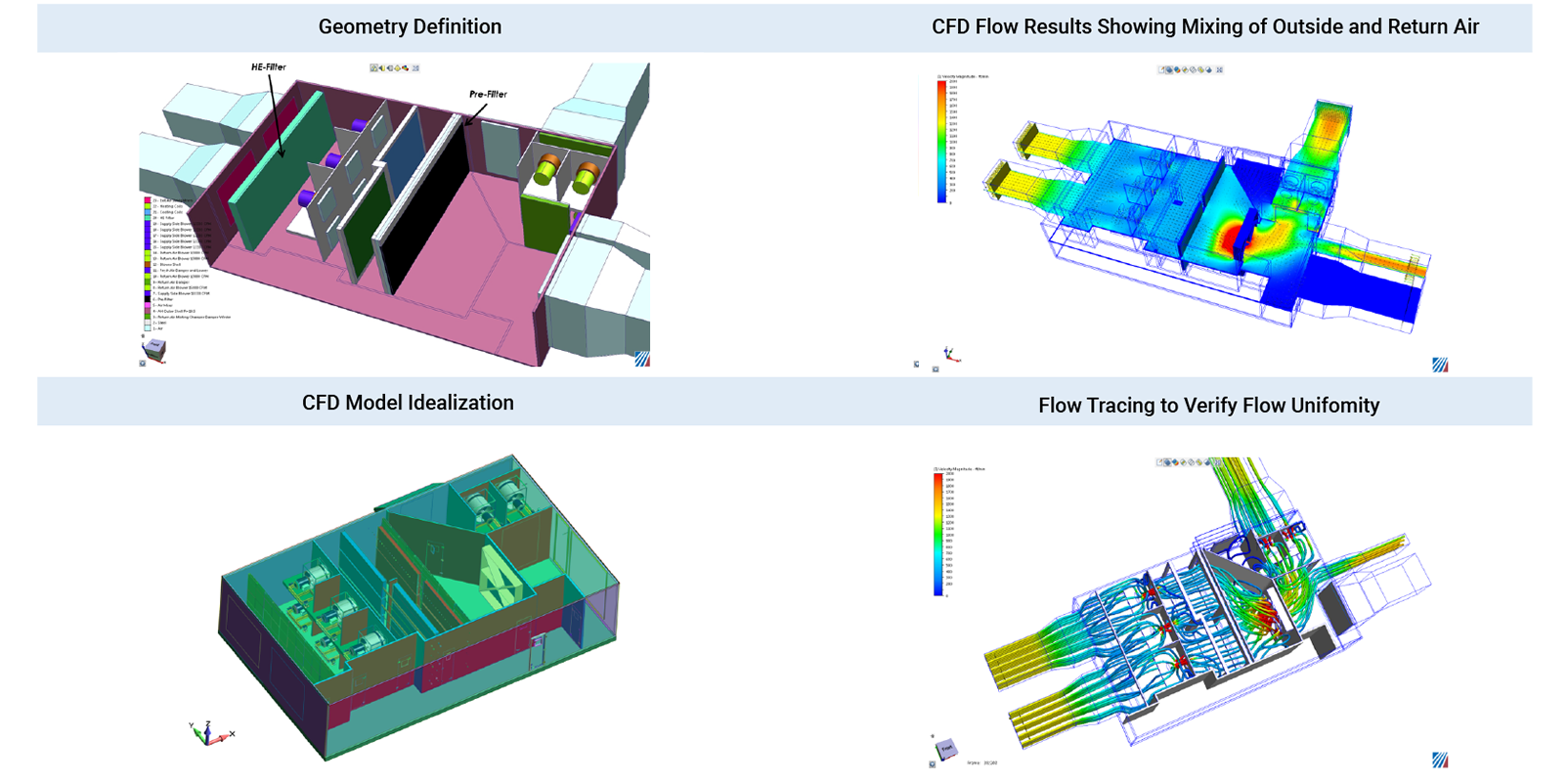

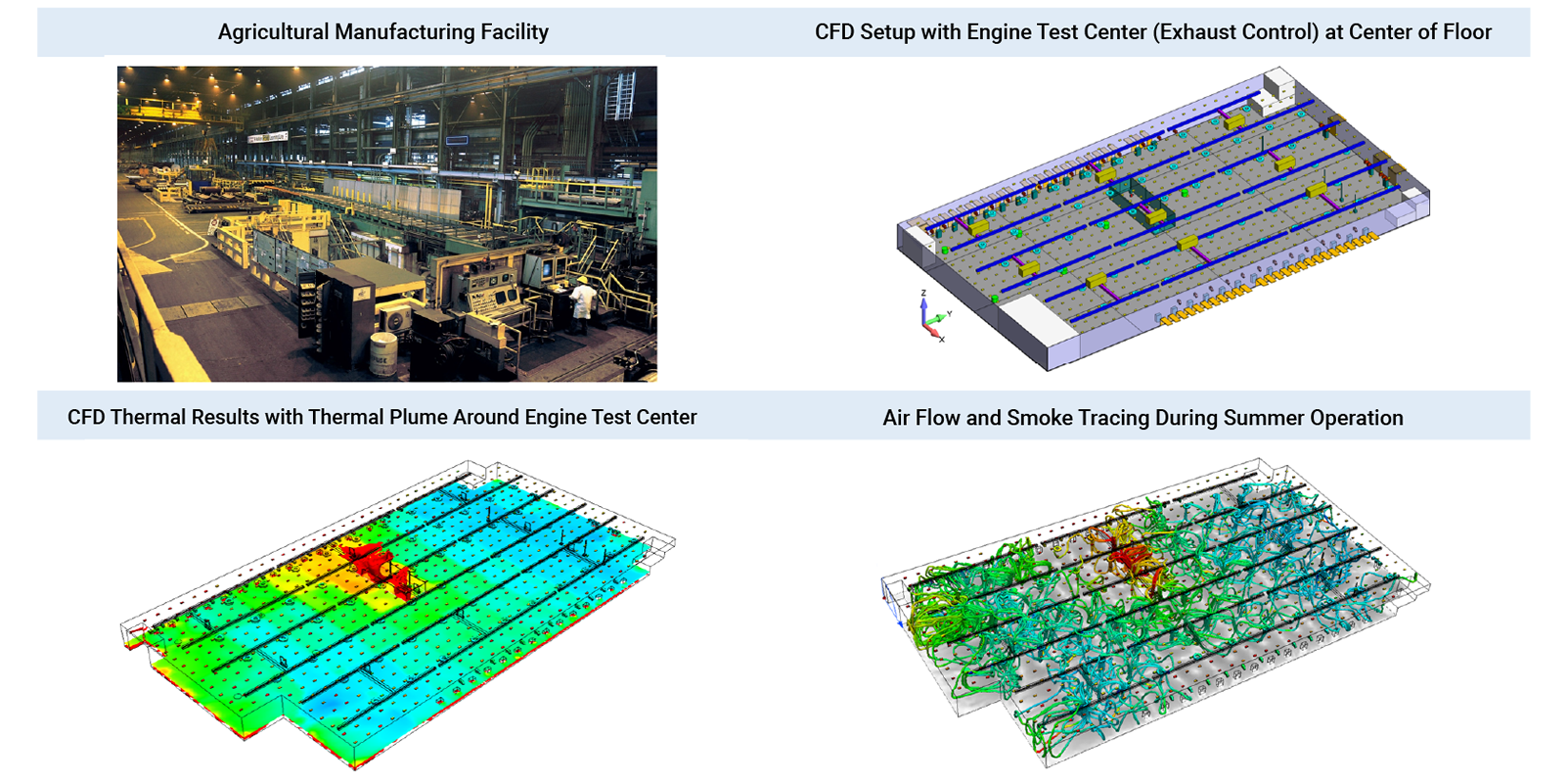

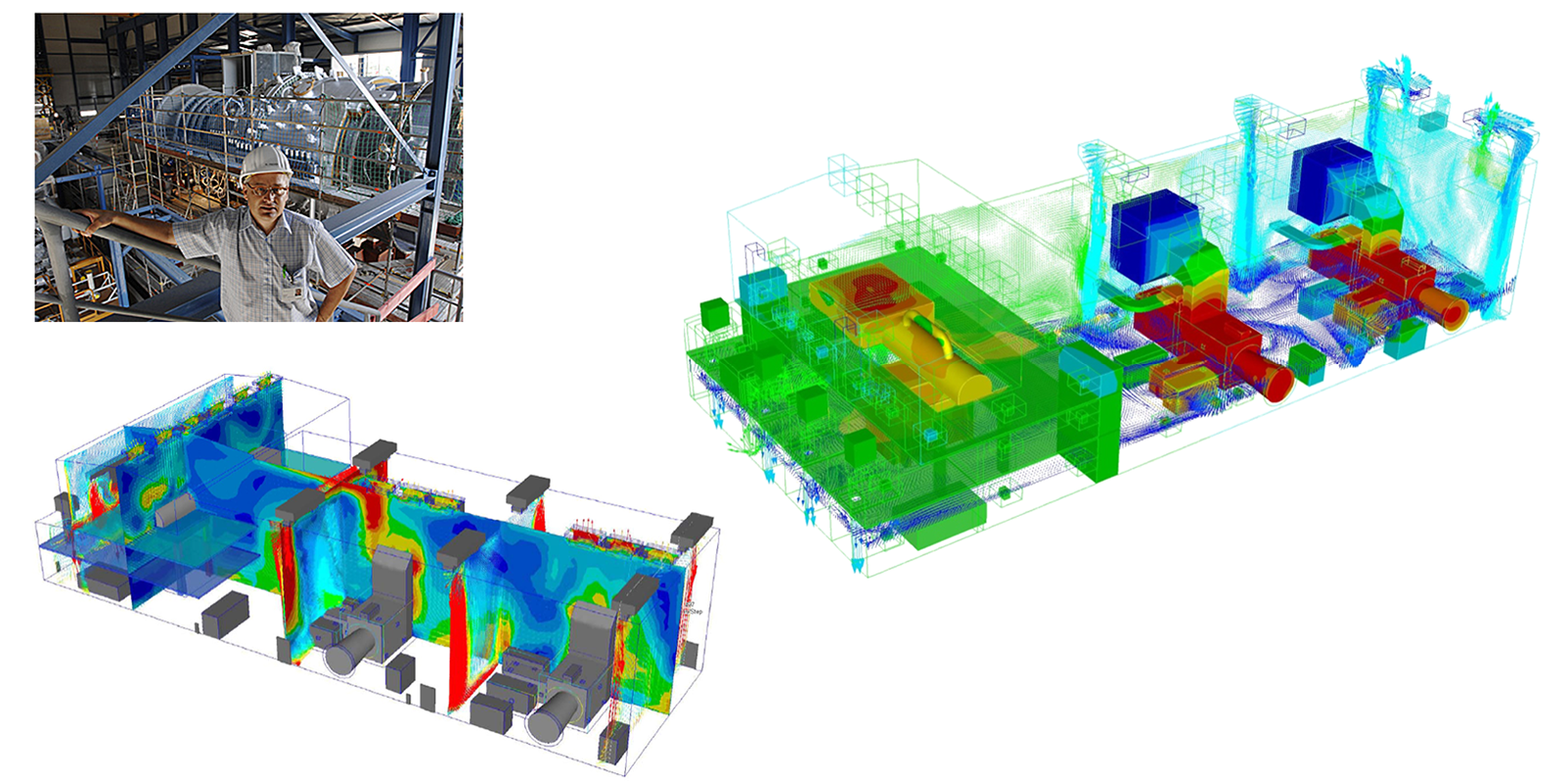

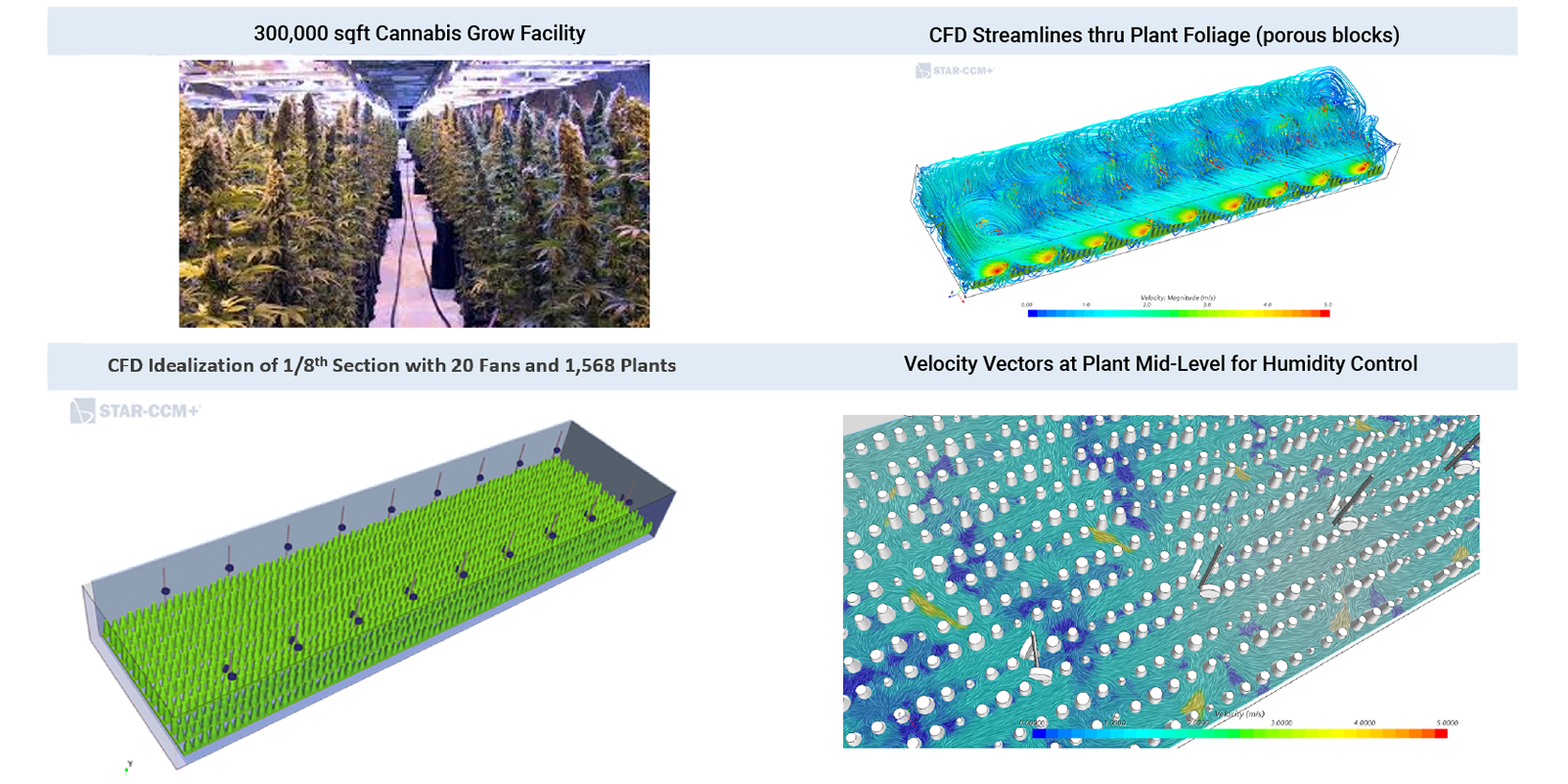

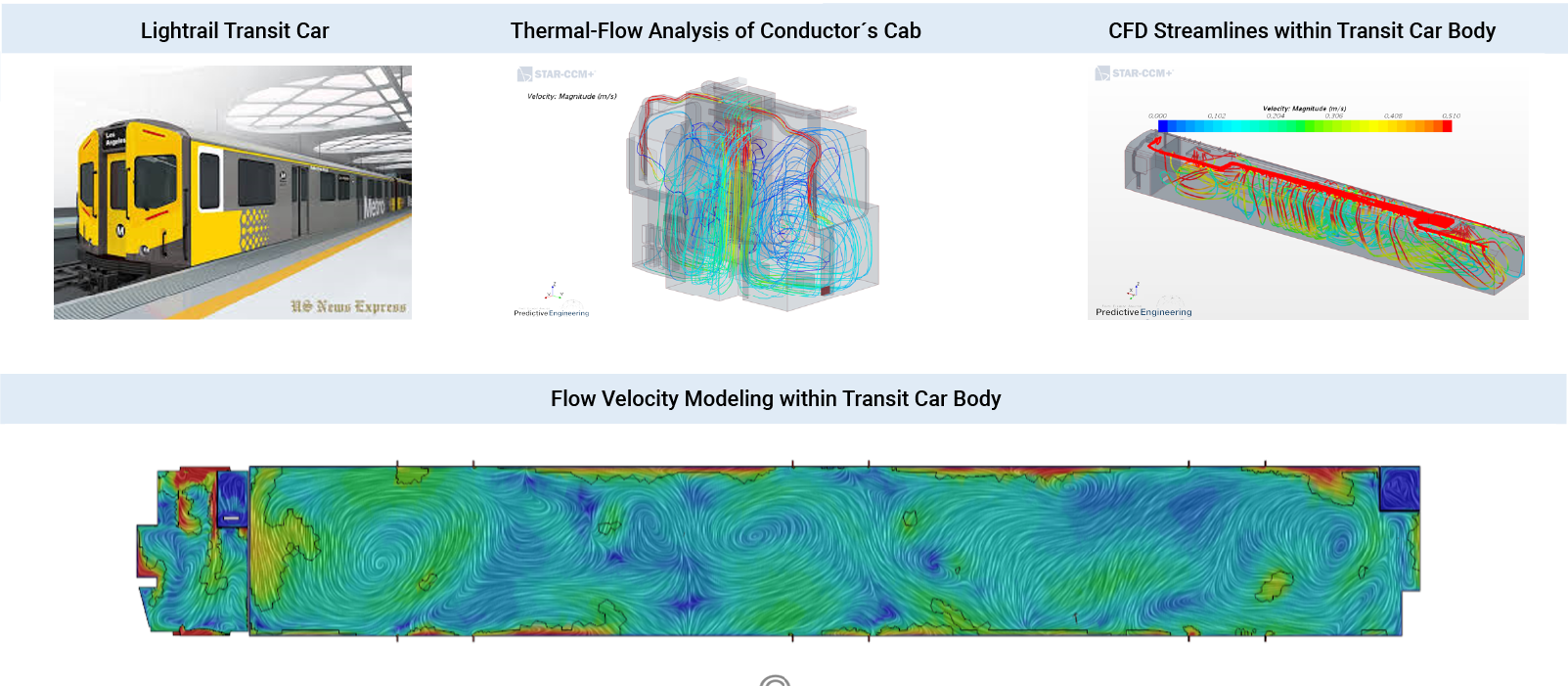

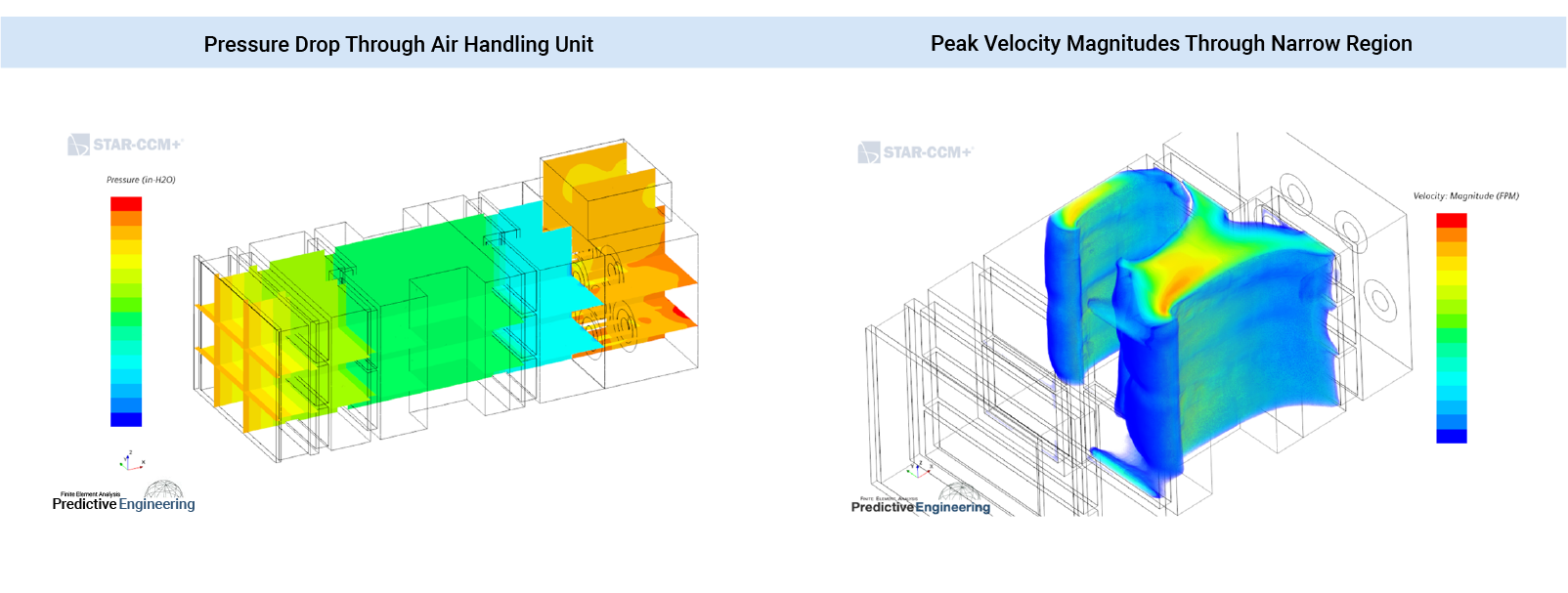

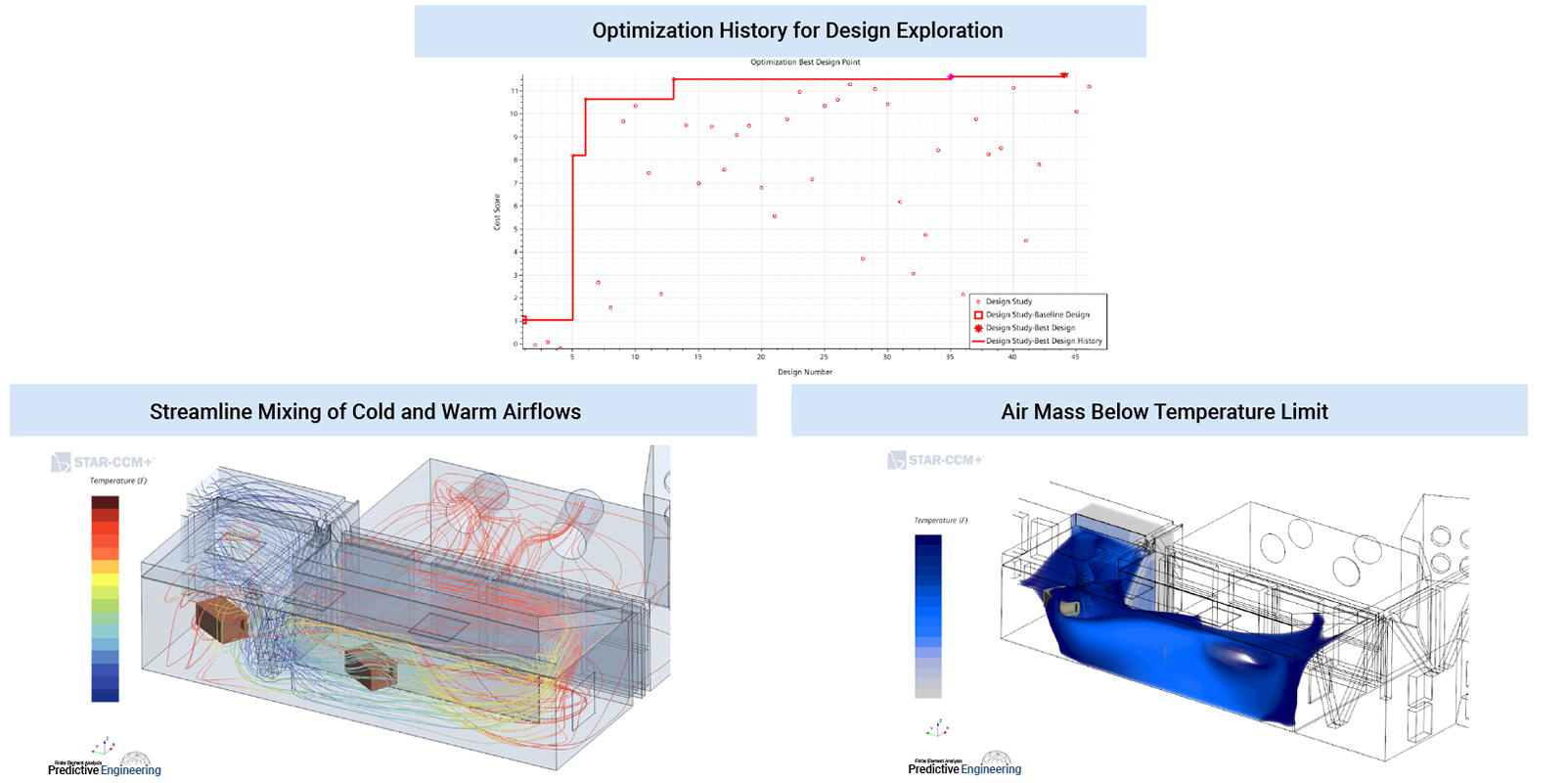

The following slides show a sample of CFD projects that are related to HVAC and building services. These projects span the range of applications from focused air handling unit performance to large factory floors. In many of these applications the end goals were to ensure an even mixing of air streams to meet criteria for uniform temperature distributions. The possible loading conditions for these type of analyses include varying flow streams, internal heat generation, internal vapor generation, and external heat from ambient and solar conditions.

PDF Download