Thermal Analysis of Integrated Circuit Cable Assembly

Analysis

Objective

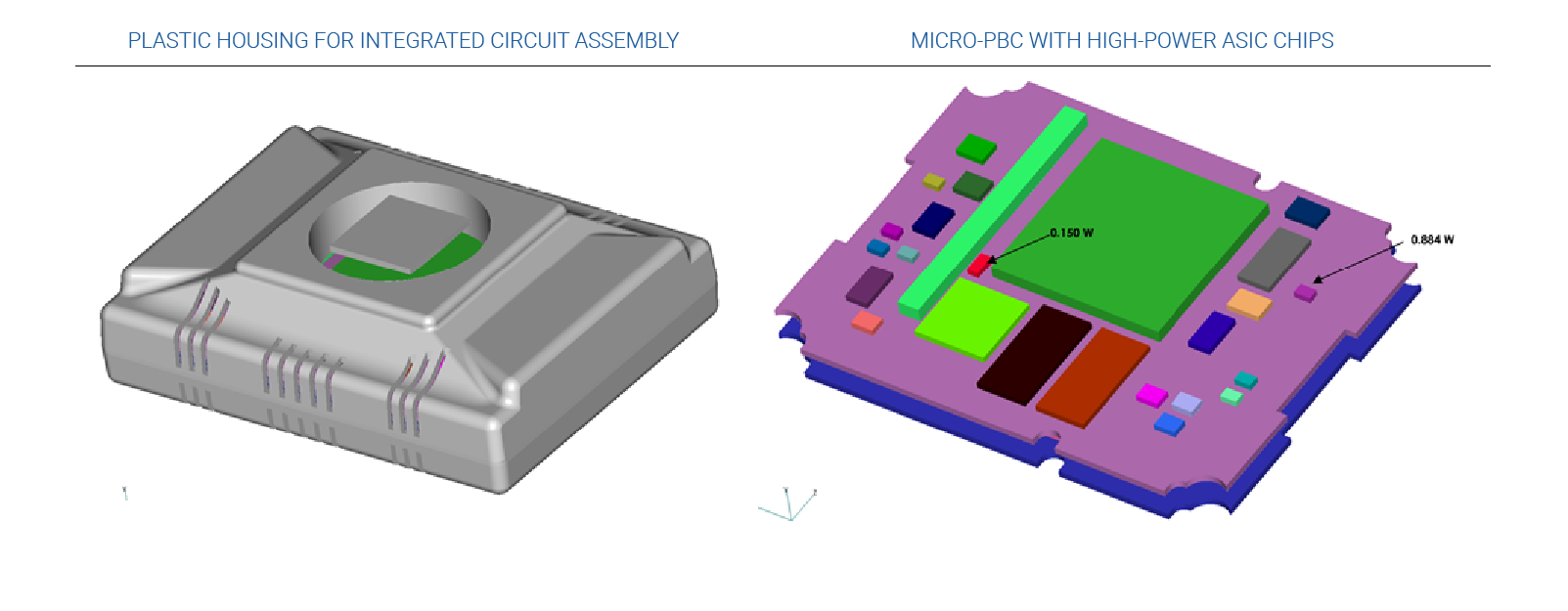

Computational fluid dynamics (CFD) analysis of a new compact data processing cable for a world leader in the design and manufacture of complete, turnkey integrated circuit cable assemblies for OEMs of ultrasound, surgical, and high speed data operations.

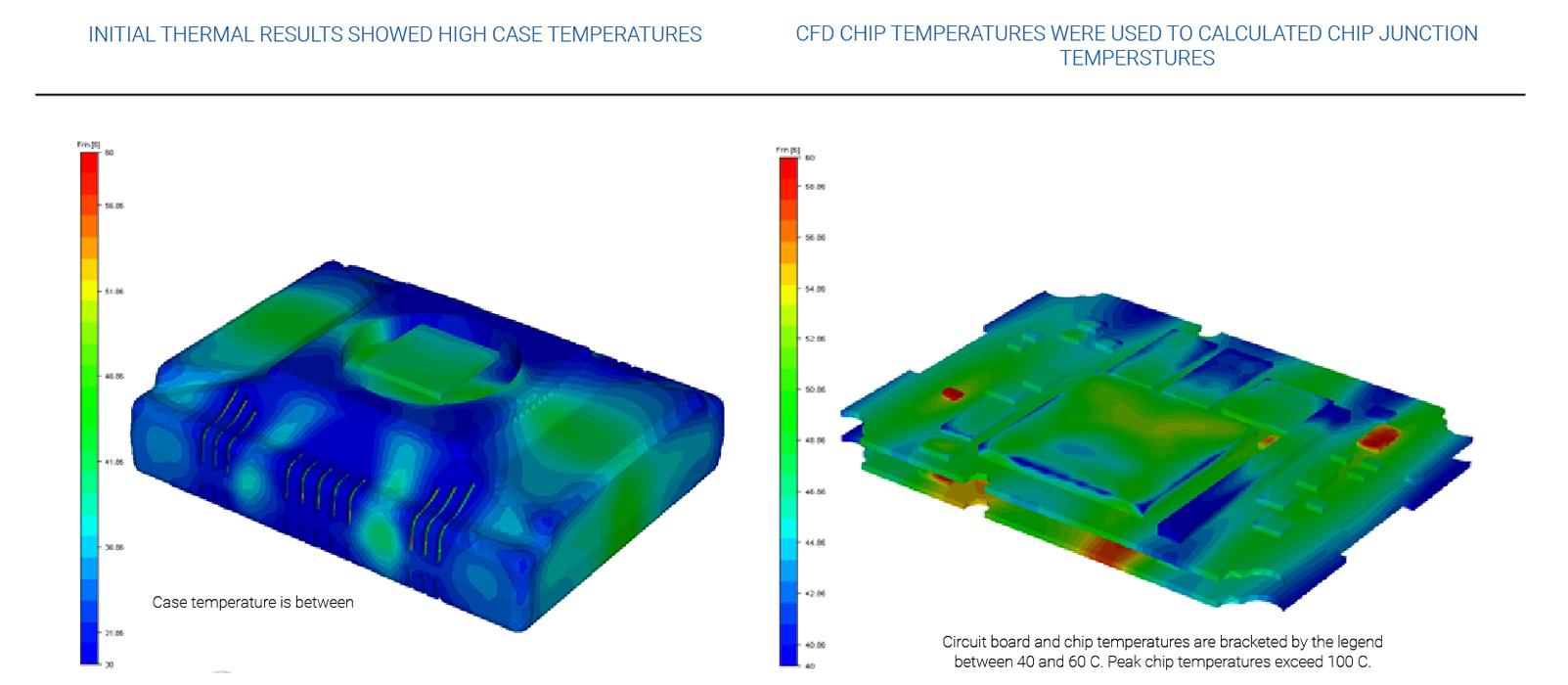

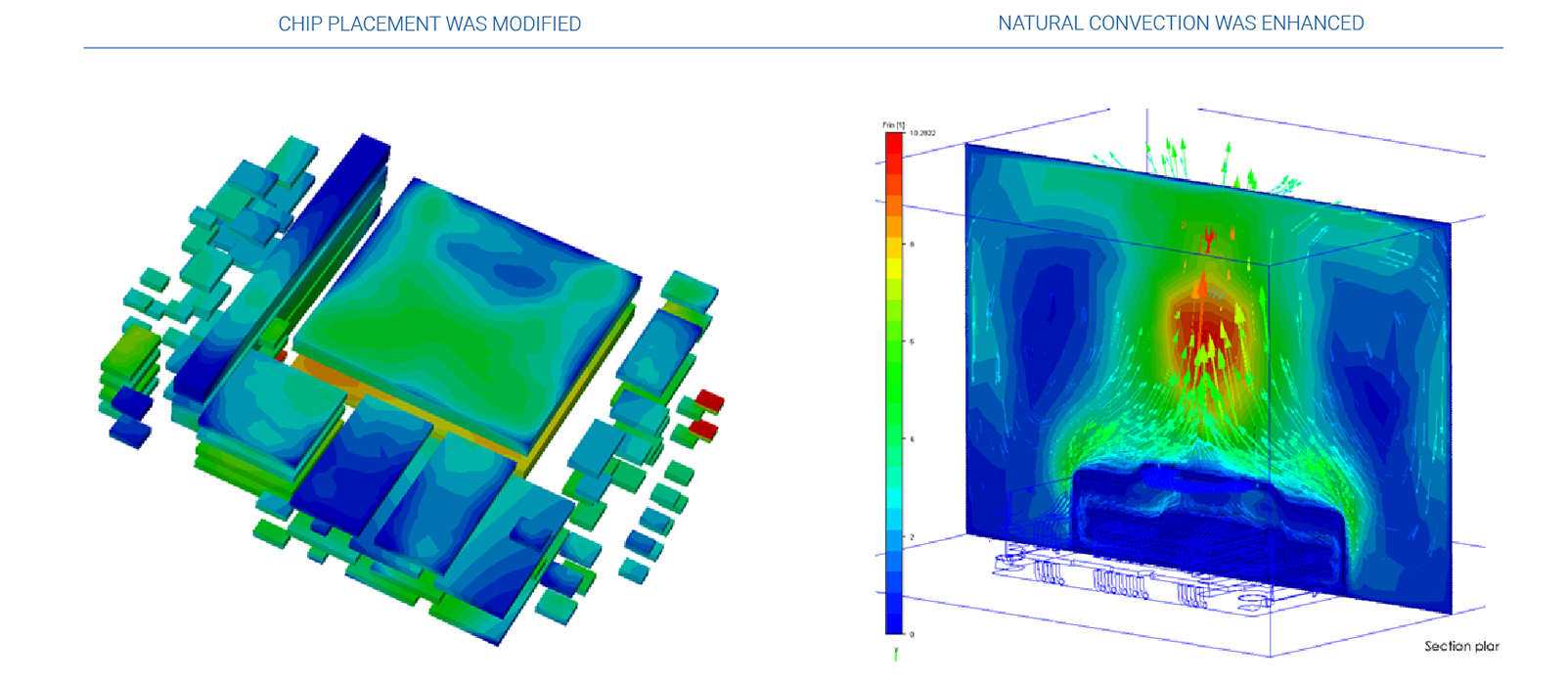

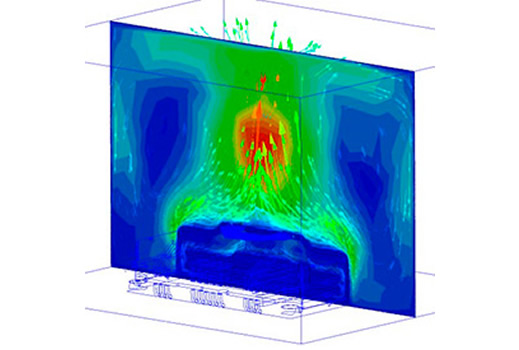

Conjugate convective-conductive thermal-fluids analysis was performed on a high-power integrated circuit board enclosed within a plastic case. Various cooling scenarios were investigated (forced cooling via a small embedded fan and natural convection). Our goal was to collaboratively work with the clients' designers to obtain a thermal solution that would provide chip junction temperatures within an acceptable range. Leveraging our CFD consulting expertise, several different approaches were advocated but due to design constraints the final solution involved the regulating the power flow to avoid peak temperatures.

Modeling notes: Based on these CFD analyses, the circuit board chip density and power density (watt loading per chip) was optimized for long term thermal reliability. One of the challenges of this work was to assure convergence of the CFD model due to localized high power density in small chips and the simulation of natural convection within a large volume.

Summary: The cable assembly has gone into production and is meeting its thermal objectives.

PDF Download