Blast Analysis of Large Generator Housing

Analysis

Objective

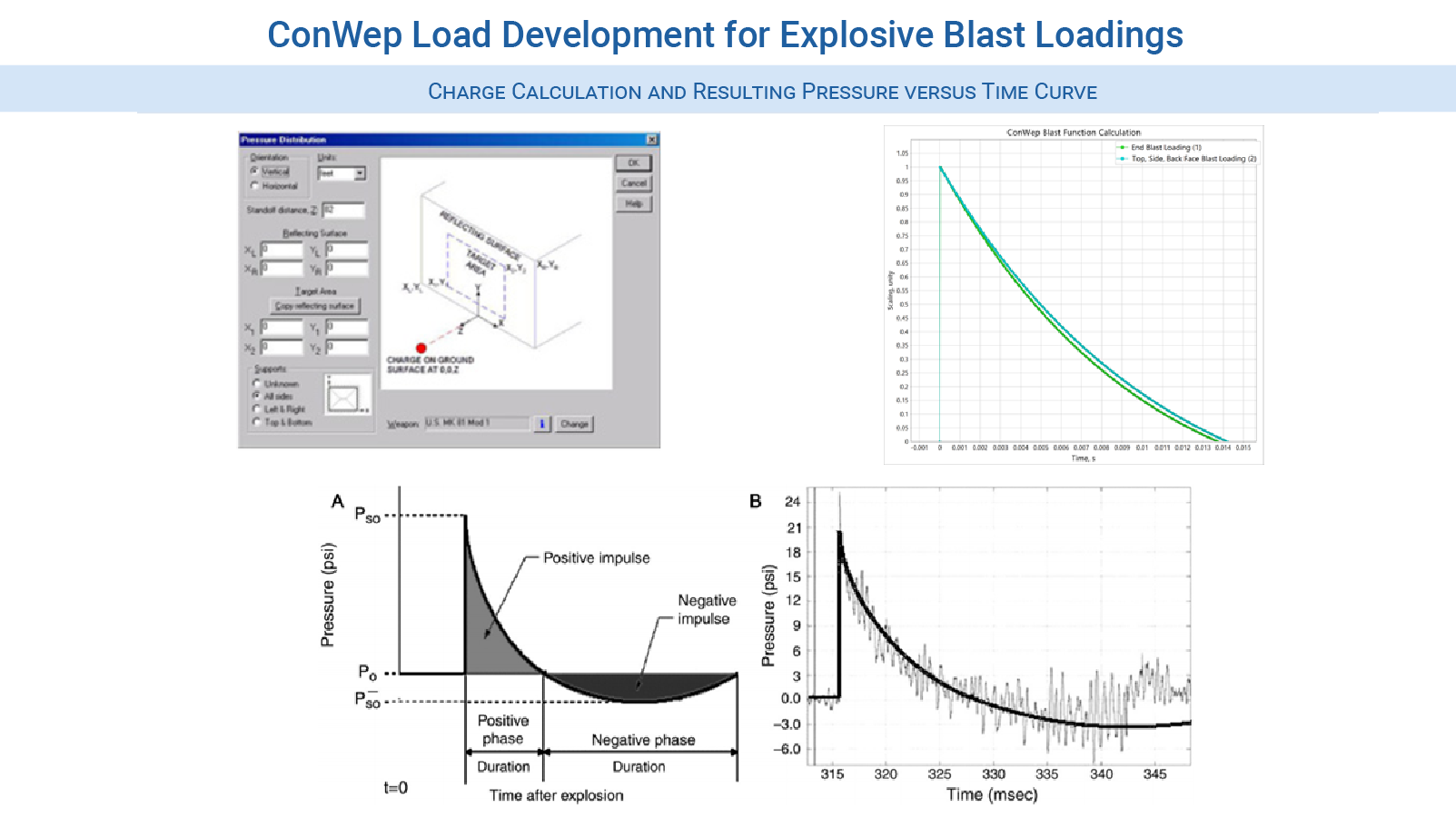

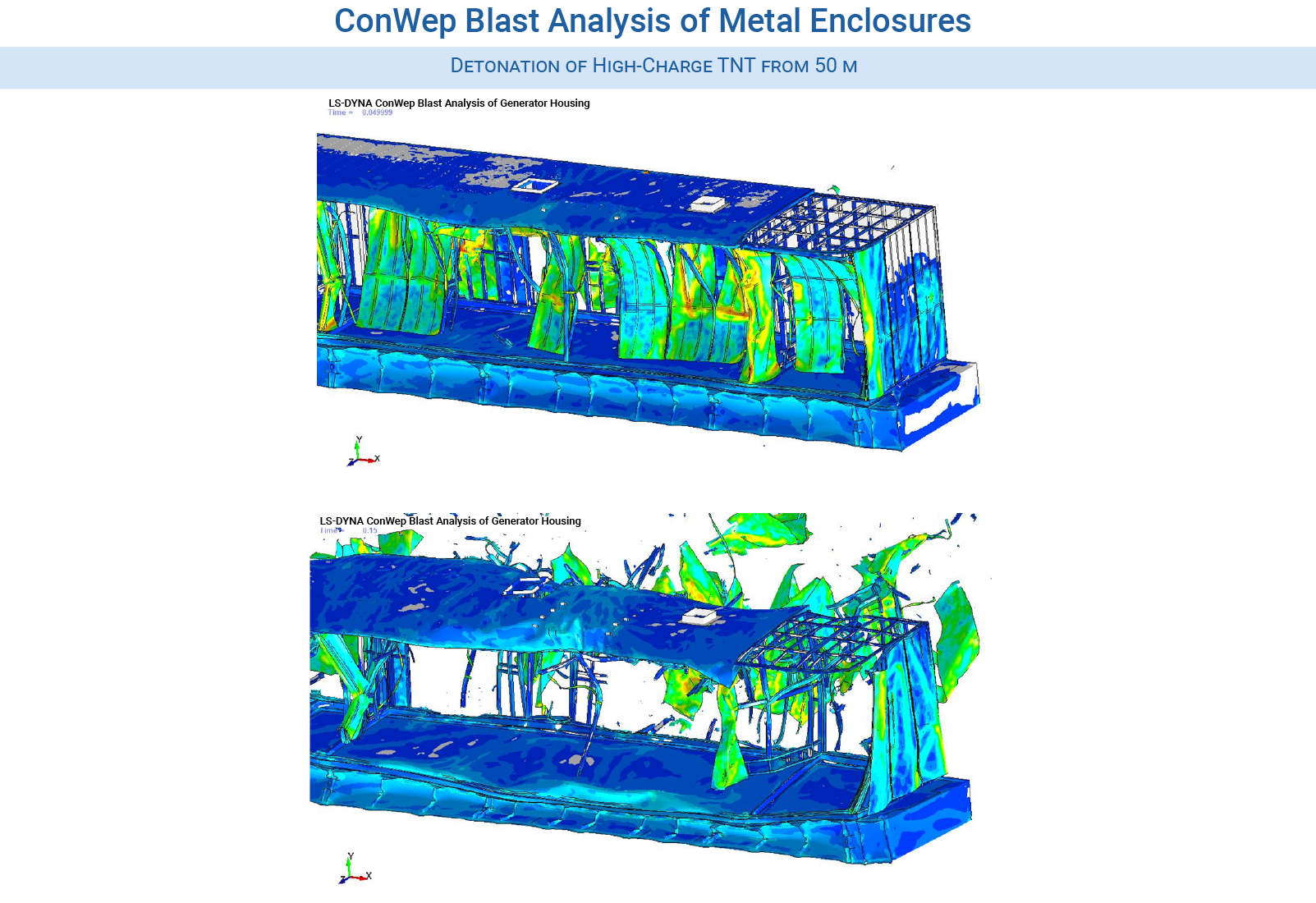

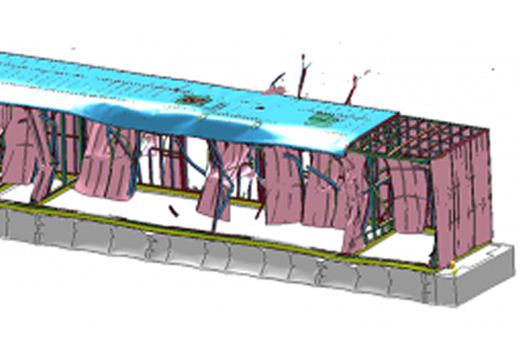

Large, skid mounted, mobile generators are quite common to supply emergency back-up power at military bases or in remote locations where the local power grid may be unstable. The power output of these generators can range from hundreds of kW up 3 MW. The systems are designed to be completely self-contained with the fuel tank as its base. In some environments, the generator housings are required to withstand blast loadings due to the detonation of ground or airborne explosives (e.g., TNT). To avoid the cost of testing a complete generator set, procedures allow for the virtual simulation of the blast event using LS-DYNA. The blast intensity can be estimated using ConWep (Conventional Weapons Effects) based on TNT charge and the structure’s distance from the charge.

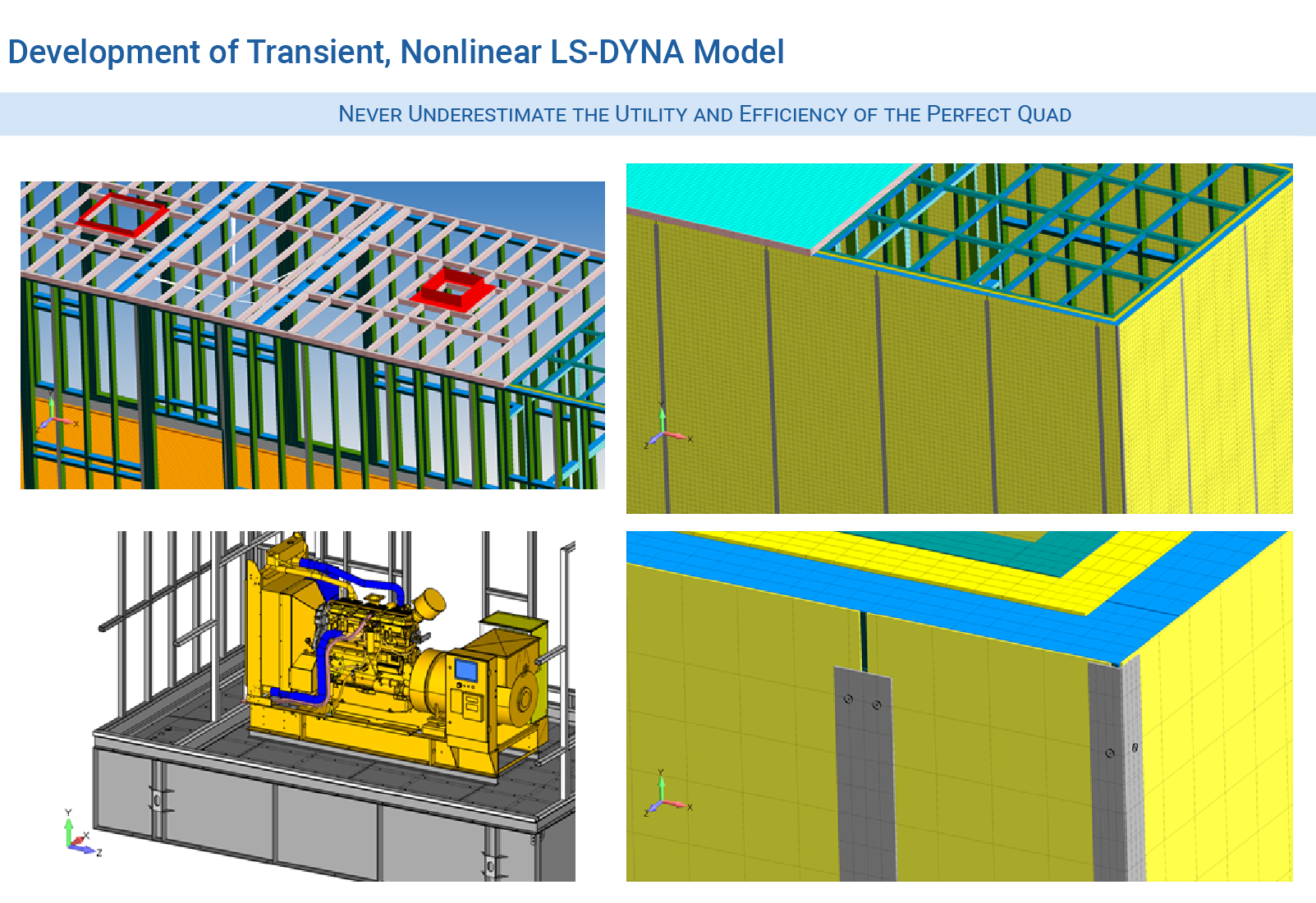

CAD geometry of the generator housing was idealized into a quad-dominate shell FEA model. The housing is a space-frame structure composed of structural steel tubing. This frame is then covered with lightweight metallic panels that are attached via self-taping screws. The frame and panels were all modeled with shells with the screws as beam elements connected node-to-node. Contact was enforced between all components to capture the interaction of the panels slamming against the ribs and other internal components.

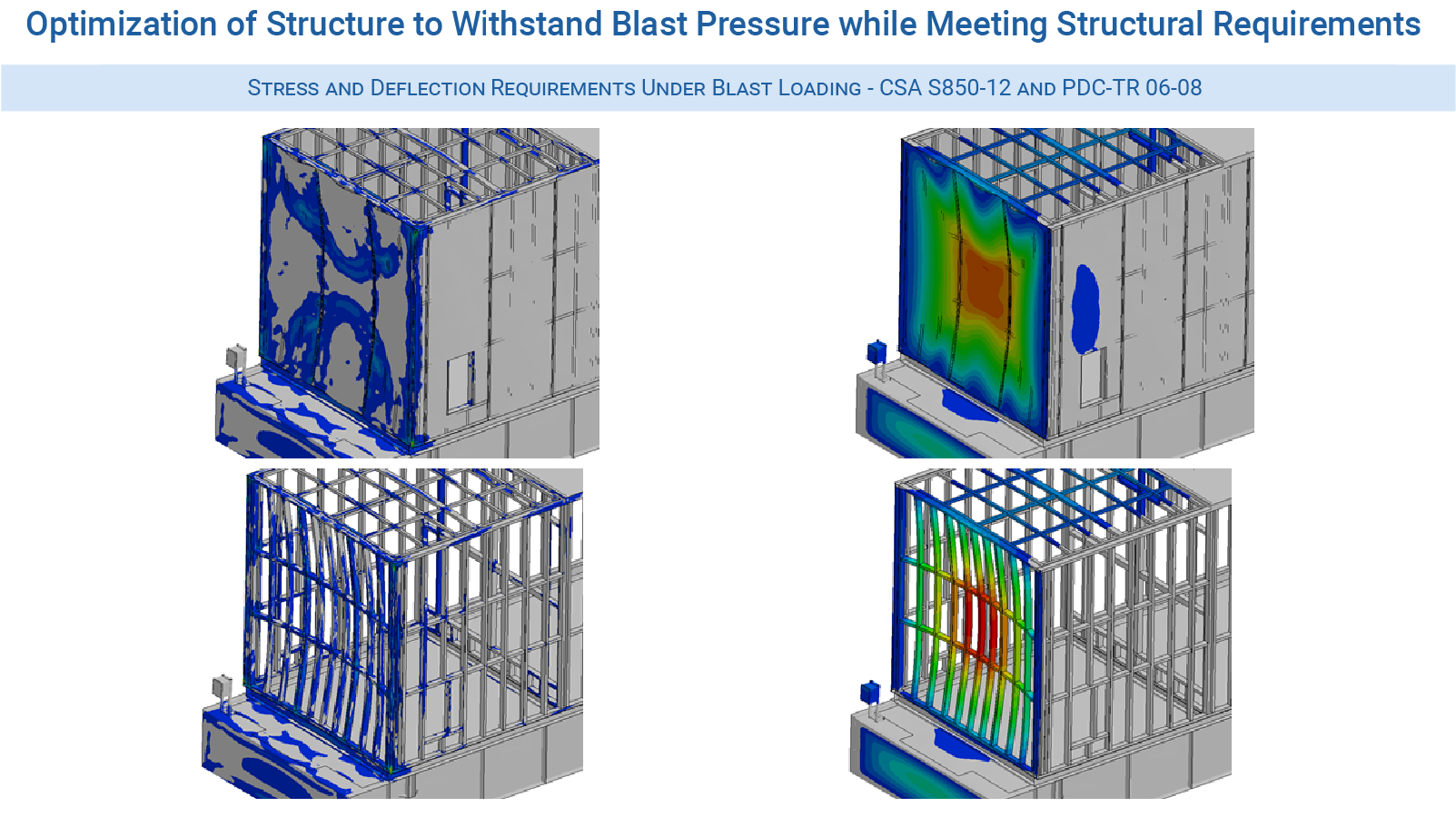

The first pass through the work was to meet the CSA S850-12 and PDC-TR 06-08 Protective Design standards and once these requirements were met, the structure could be optimized to improve its manufacturability. Upon the final simulation, the survivability of the housing was shown to pass and that improvements in manufacturing and weight reduction essentially paid for the consulting engineering work.

PDF Download

LS-DYNA Consulting Engineers - ConWep Blast Analysis of Large Generator Housing