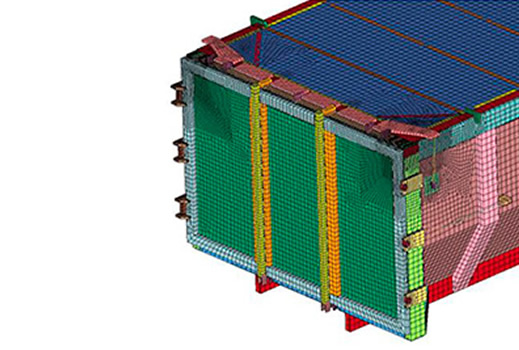

Drop Test Analysis of Large Nuclear Waste Storage Containers

Analysis

Objective

The U.S. Department of Transportation specification 49 CFR 173 calls out a rigorous series of testing procedures for containers that are used to transport hazardous waste. One requirement is that the container survive a drop test from certain height The height of the drop test is determined by the weight of the container.

As the weight of the container increases, the drop height decreases. As an example, a 50,000 lbf container must survive a drop from 12" onto its most vulnerable corner. Over the years, as the sophistication of computer programs has increased and the accuracy of the real world simulations has improved, the DOT has allowed the substitution of conservative numerical results for actual drop testing. A numerical standard in the industry for drop testing is LS-DYNA from LSTC (see www.LSTC.com). This explicit/implicit FEA code is quite amazing in its ability to accurately capture extreme nonlinearities in a transient event. Although its bread and butter is the simulation of car crashes...the drop testing of large steel containers and the high speed impact analysis of cars are quite similar. Both involve dynamic events where multiple contacting surfaces must be handled quickly and large plastic strains dealt with in a realistic manner.

The successful completion of this project owes many thanks to the fine engineering tools provided by LSTC (the manufacturers of LS-DYNA) and by Siemens (the manufacturers of FEMAP and NX CAD). Not only are their software tools world class but their technical support infrastructure is second to none.

The key analysis words for this project are: LS-DYNA, Femap, Impact Analysis, Drop Testing, and DOT 49CFR173