08

Mar

2024

News and Updates

News, Blogs and Updates

13

Nov

2023

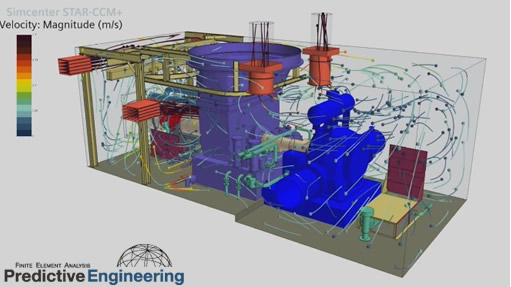

Airflow dynamics within a room or an enclosure can have significant impact on human thermal comfort, production efficiencies, and even safety.

18

May

2023

With the rise of artificial intelligence (AI), the world is experiencing another sea change in events.

23

Mar

2023

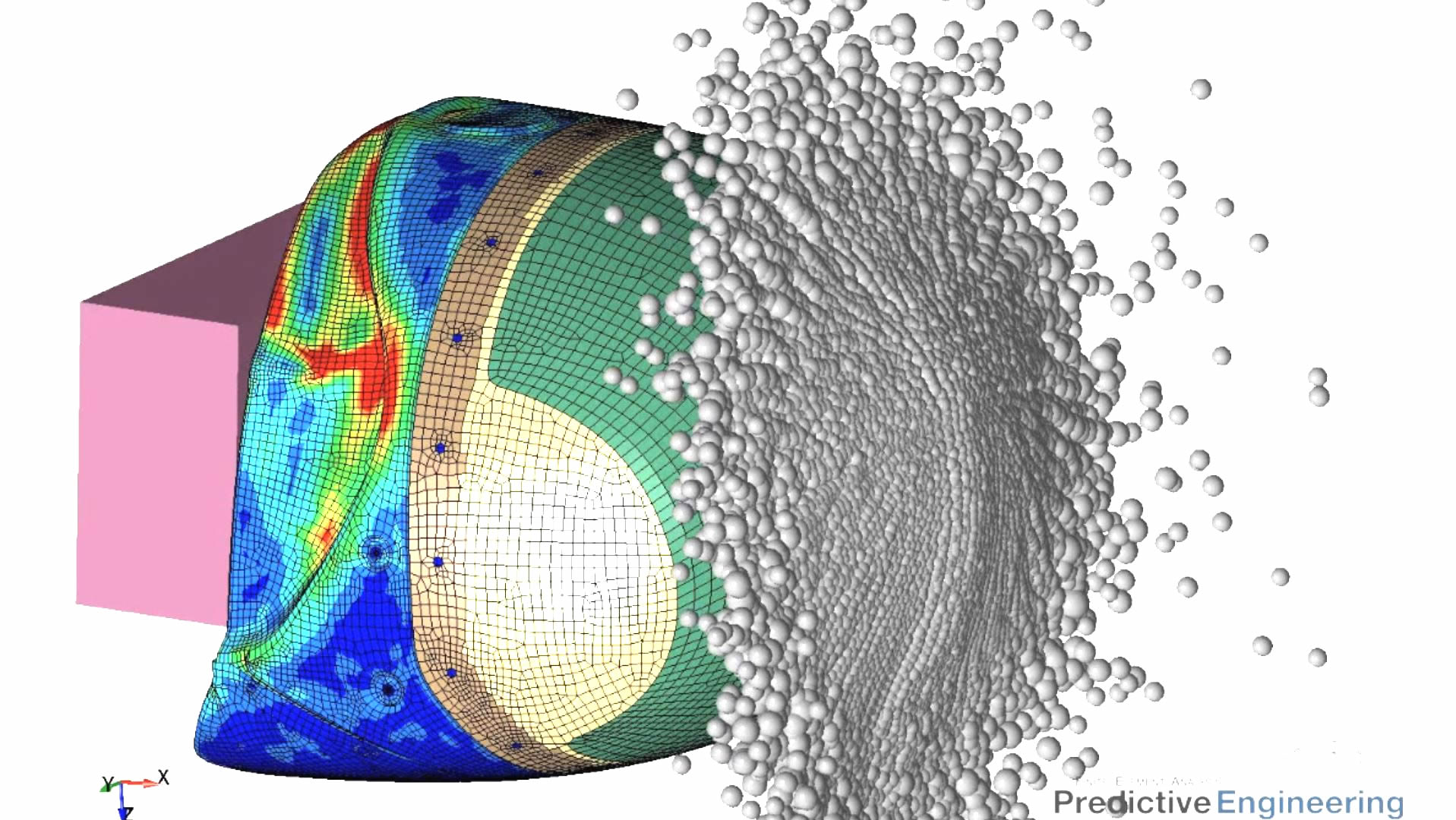

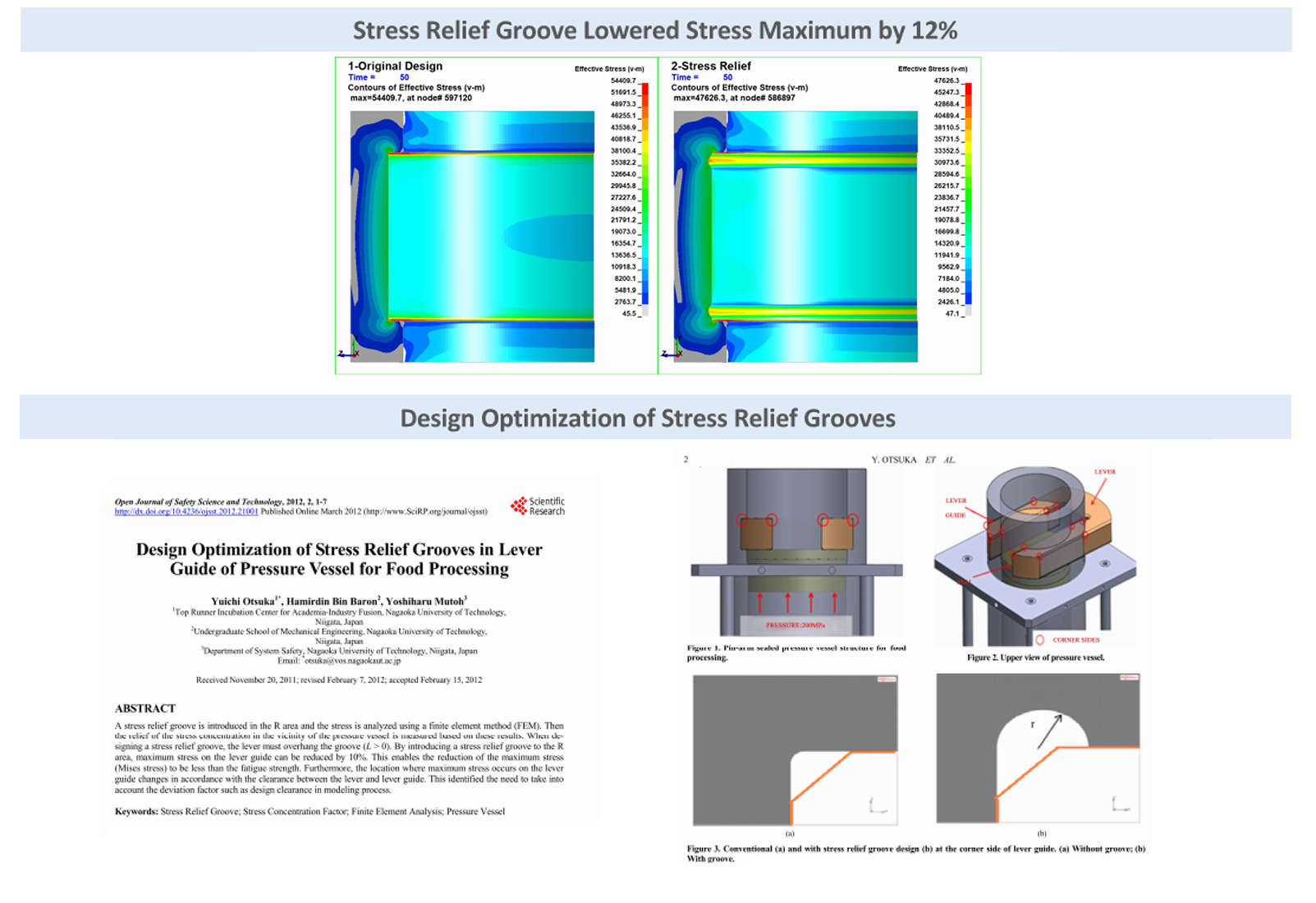

Pressure vessels and even composite pressure vessels, are nothing new, so why the write-up? Energy storage has been the thorn in the side of the green energ

22

Sep

2022

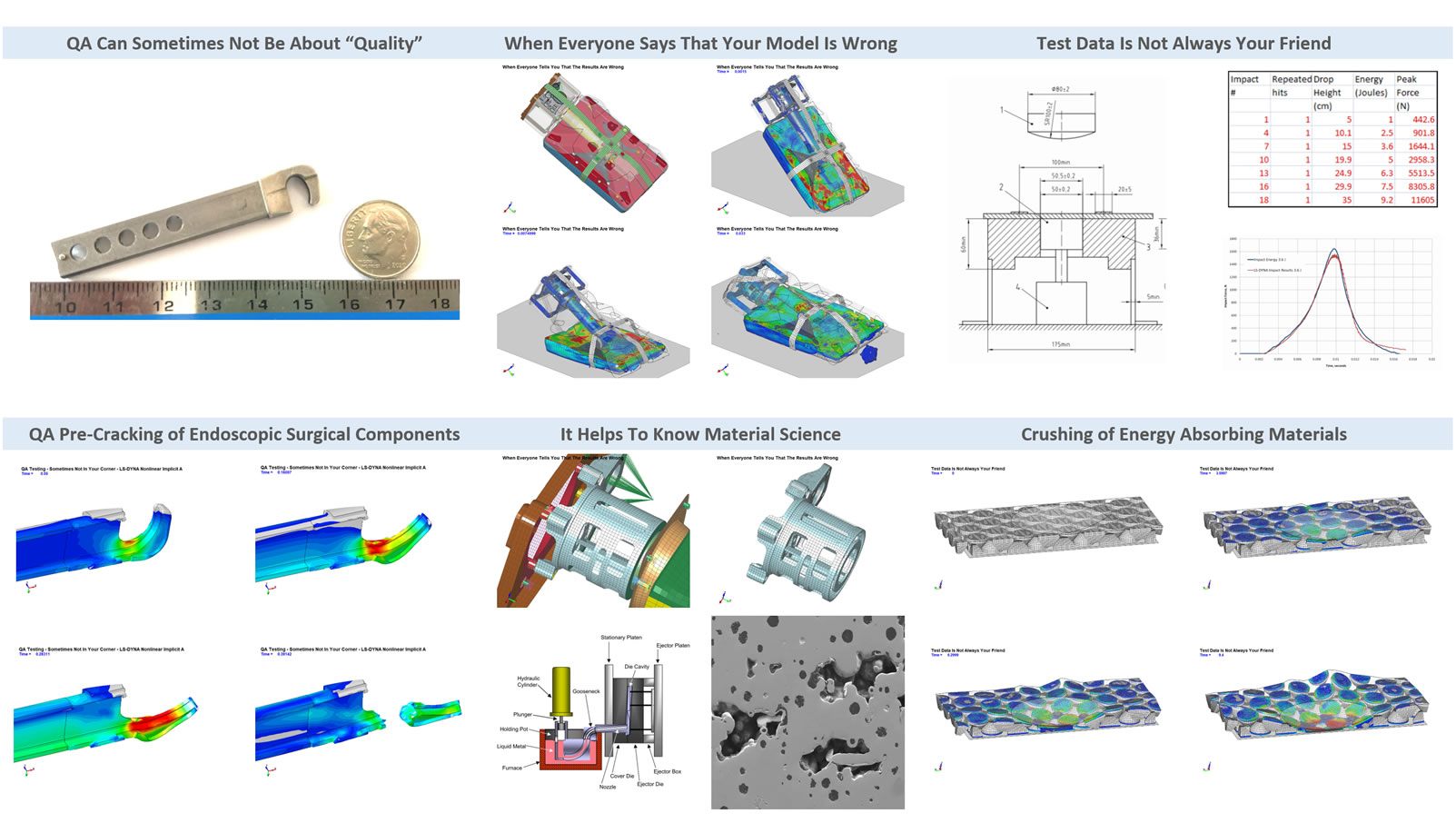

I was stumped the other day when a client asked me “How can your FEA results help us design better QA experiments?” I had no easy answer, and it was a bit d

03

May

2022

Yes, it is a “blog” and that means I can write about whatever engineering topic that catches my fancy. Today it is classic mechanics and although we have th

Our Partners