ASME Section VIII Pressure Vessel - Nozzle Load Application with Software Automation

Analysis

Objective

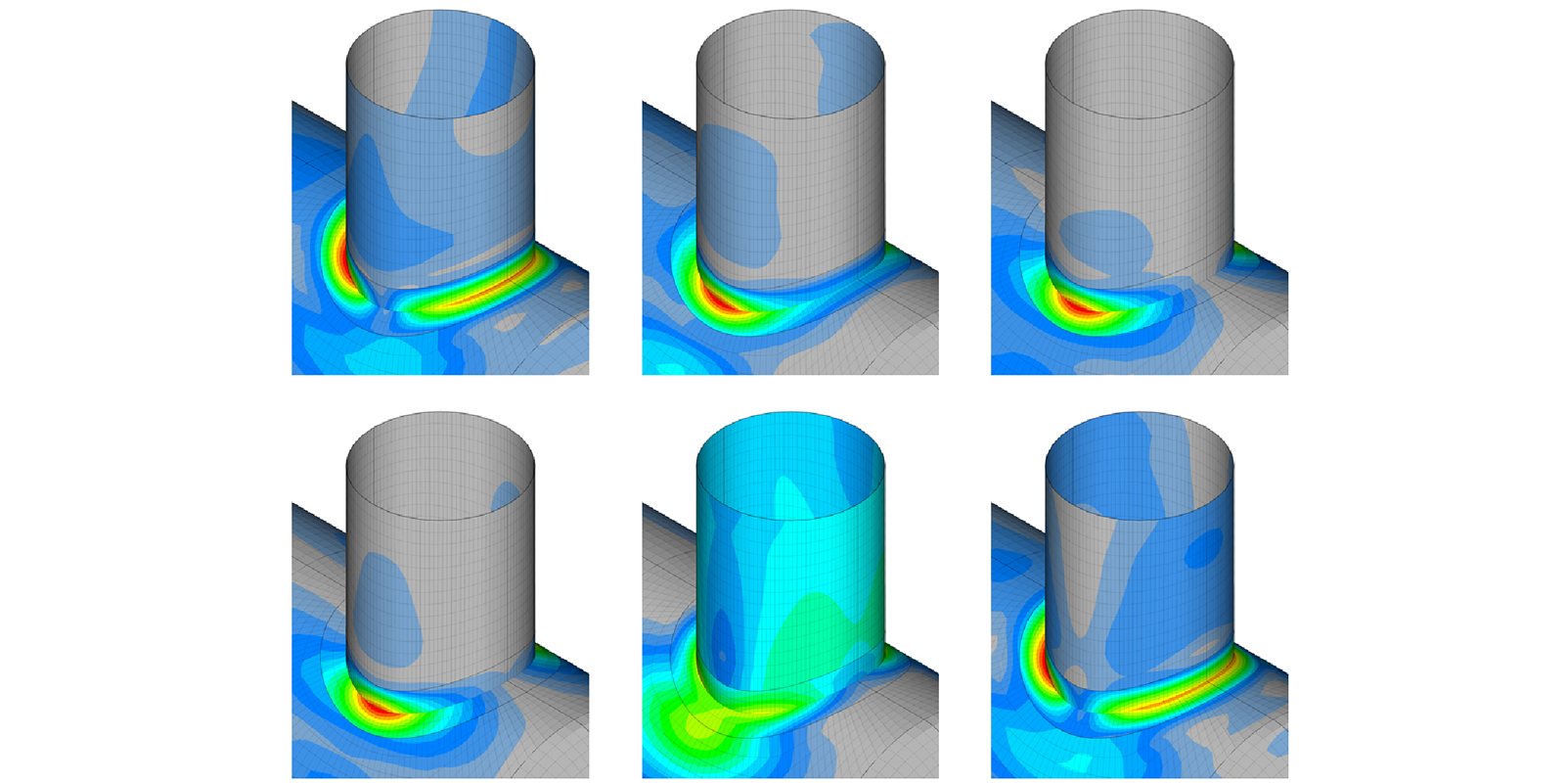

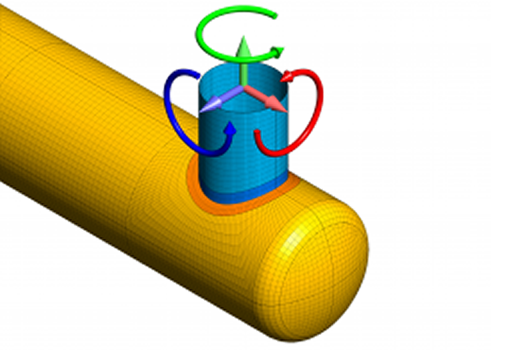

Generally, the nozzles of an ASME Section VIII pressure vessel can be checked with hand calculations. A simple nozzle on a flat head is a perfect example of a structure that can be idealized as a cantilever beam. For more complex shapes, numerical analyis allows optimization and cost reduction.

Finite element analysis can quickly provide accurate stress numbers for a complete range of nozzle and shell configurations. What is not well-known is that this process can be automated.

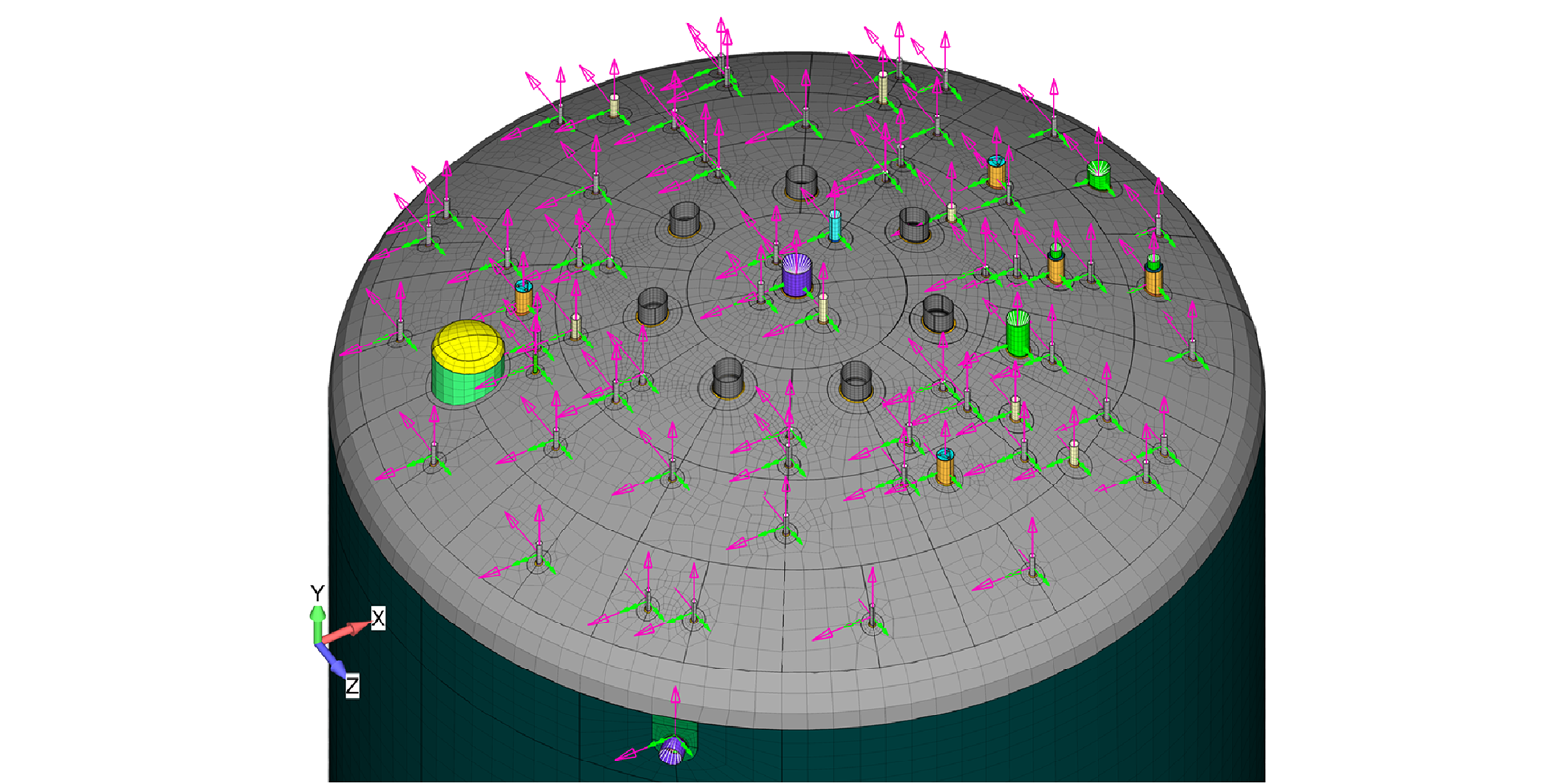

For the vessel in this case study, nozzle forces and moments were given for weight, seismic and thermal load cases in the X, Y and Z direction. There were approximately 70 nozzles. That results in 1,260 individual loads that need to be applied to the model. Even for the most efficient FE modeler, this task could take all day. Checking for errors in data entry doubles the work time. If the end client changes the loads, it all starts over again.

To automate this task, the Femap Application Programming Interface (API) was employed. With the load provided in a Microsoft Excel spreadsheet, a VBA macro could be written that would create the loads in Femap using the values in Excel. Every time the loads were changed, the spreadsheet would be updated and loads would be applied to the model with the click of a button.

PDF Download