Seismic, Stress, Thermal, Fatigue and Sloshing Analysis of Nuclear Waste ASME Pressure Vessels

Analysis

Objective

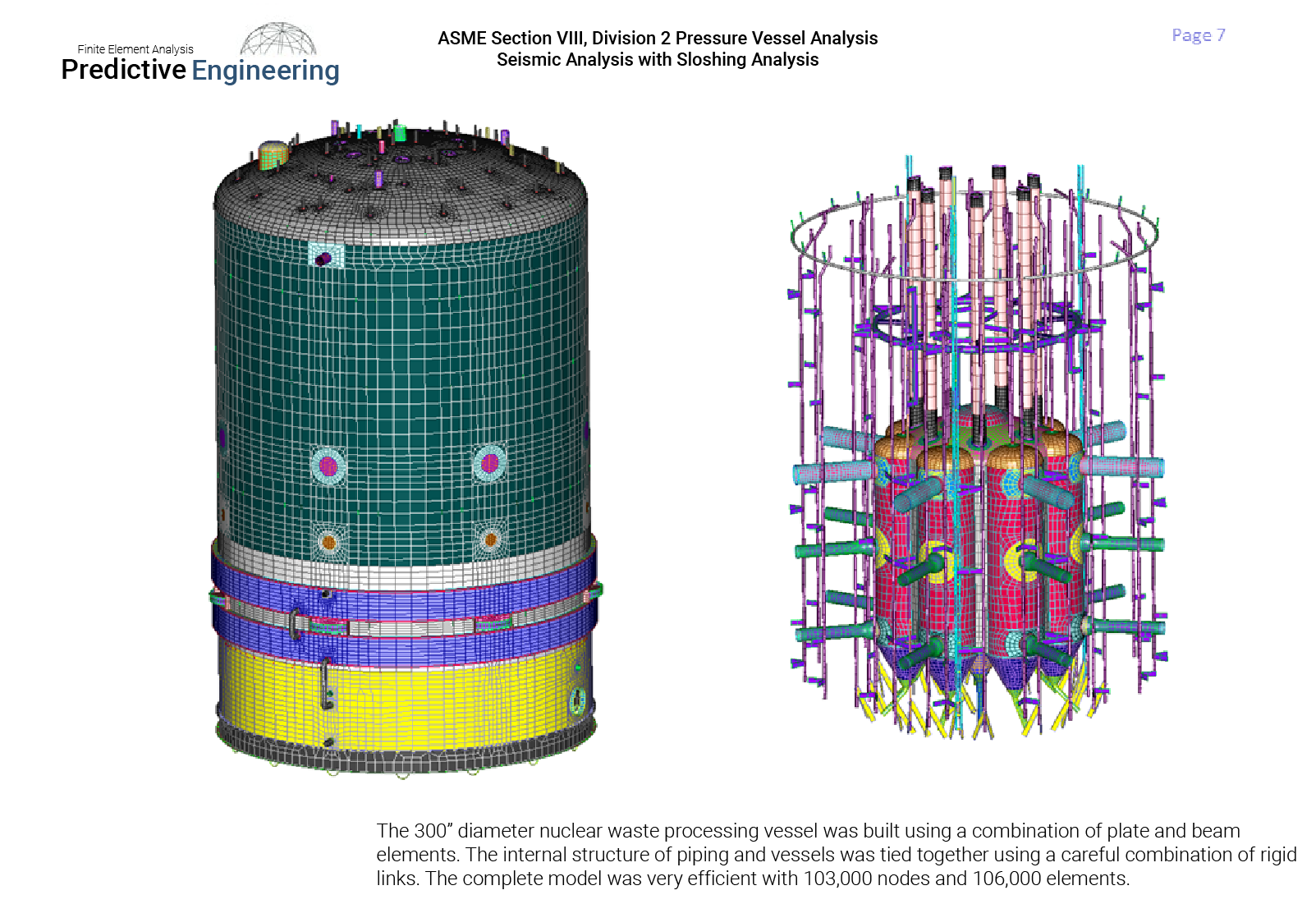

Seismic, stress, thermal, fatigue and sloshing analyses were performed on a series of large-scale (e.g., 300” diameter) nuclear waste processing vessels for the DOE. Engineering work was approved under ASME Section VIII, Div. 2, ASCE 4-98 for Seismic Analysis of Nuclear-Related Equipment and associated NQA-1 requirements.

The design and manufacture of pressure vessels might be considered a bit staid and old-fashioned by many engineers where one simply cranks through pages of arcane Code to create the proverbial bomb-proof design. For our client this might have been the case at the turn of the 20th century when they were founded; however, for the 21st century, our client is designing and manufacturing some of the most complex pressure vessels in the world. These vessels destined to process nuclear wastes left over from the Manhattan Project in Central Washington (Hanford Site) must meet extreme seismic and fatigue requirements that are pushing the limits of modern construction, design and analysis techniques. What makes these vessels so completely unique is the placement of large cluster of internal vessels within the main parent vessel. During operation, these internal vessels are cycled with high-pressure air pulses to agitate the nuclear waste sludge and prepare it for subsequent downstream processing. Additionally, a slew of other piping is installed with the vessel to inject air and steam into the sludge. This complete assembly must not only pass the ASME Section VIII, Div. 1 and 2 requirements but also the stricter and more complex ASCE 4-98 seismic and AISC N690 for buckling.

Our client has been using Femap and NX Nastran for many years to gain the competitive advantage over vessels designed under the standard ASME Code guidelines. However, the Hanford Site vessel’s presented challenges across all fronts and rather see their internal engineering team get whip-sawed to pieces and watch other on-going client projects suffer, the client decided to bring in Predictive Engineering to assist in the analysis of these specialty vessels. Predictive Engineering specializes in seismic and fatigue analysis of large complex structures and relies upon Femap and NX Nastran to deliver accurate results that can meet the most stringent of Department of Energy (DOE) nuclear quality requirements.

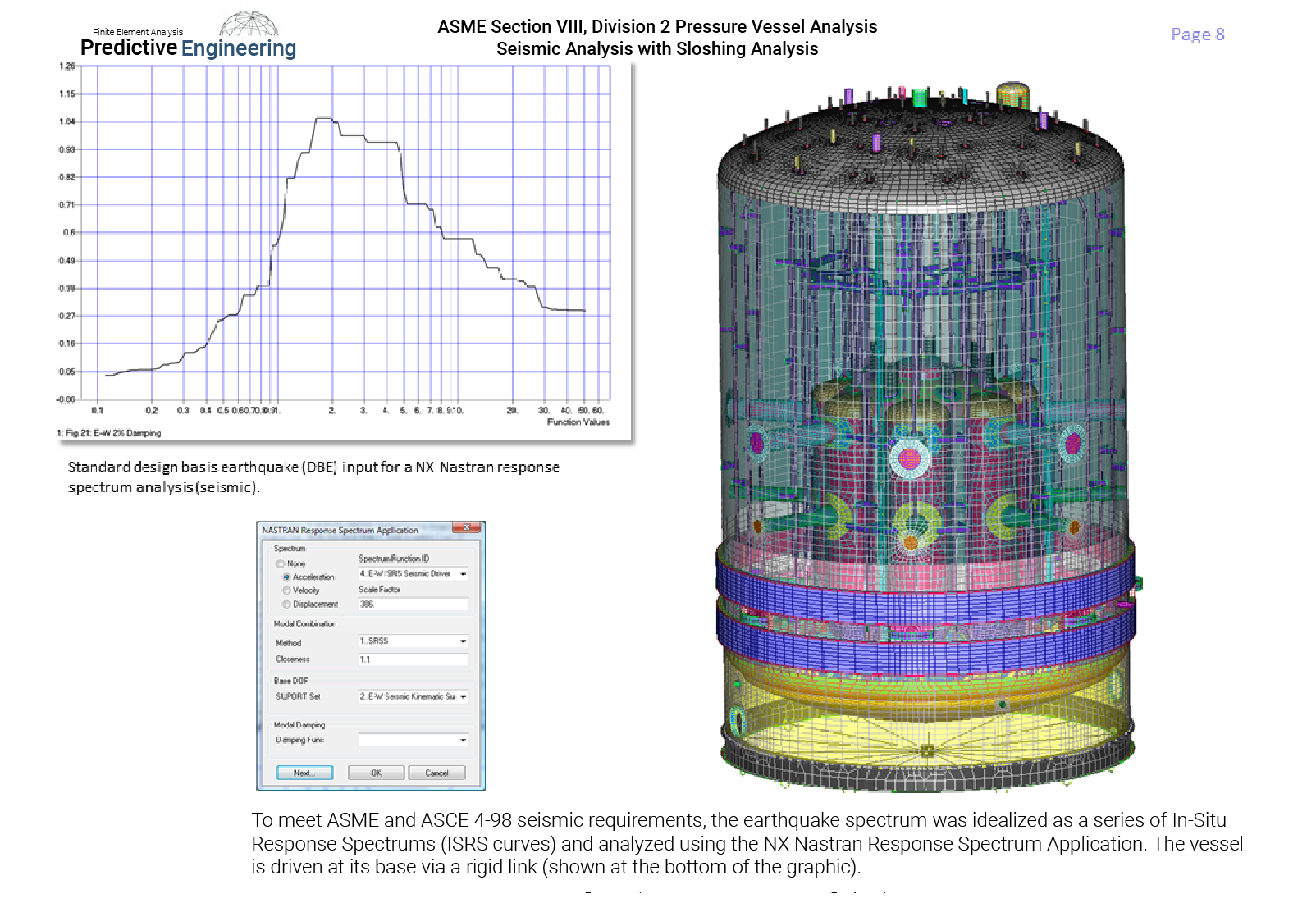

The foundation of any seismic analysis is the basic numerical technique of normal mode superposition or response spectrum analysis. This core NX Nastran technology has been proven from the Saturn moon launch to the design of our super-quiet and smooth driving trucks and autos. The analysis procedure is actually quite simple within NX Nastran. The model is given a design basis earthquake (DBE) and by setting a few parameters as required by the ASCE 4-98 Seismic Code, NX Nastran generates the required results for Code verification.

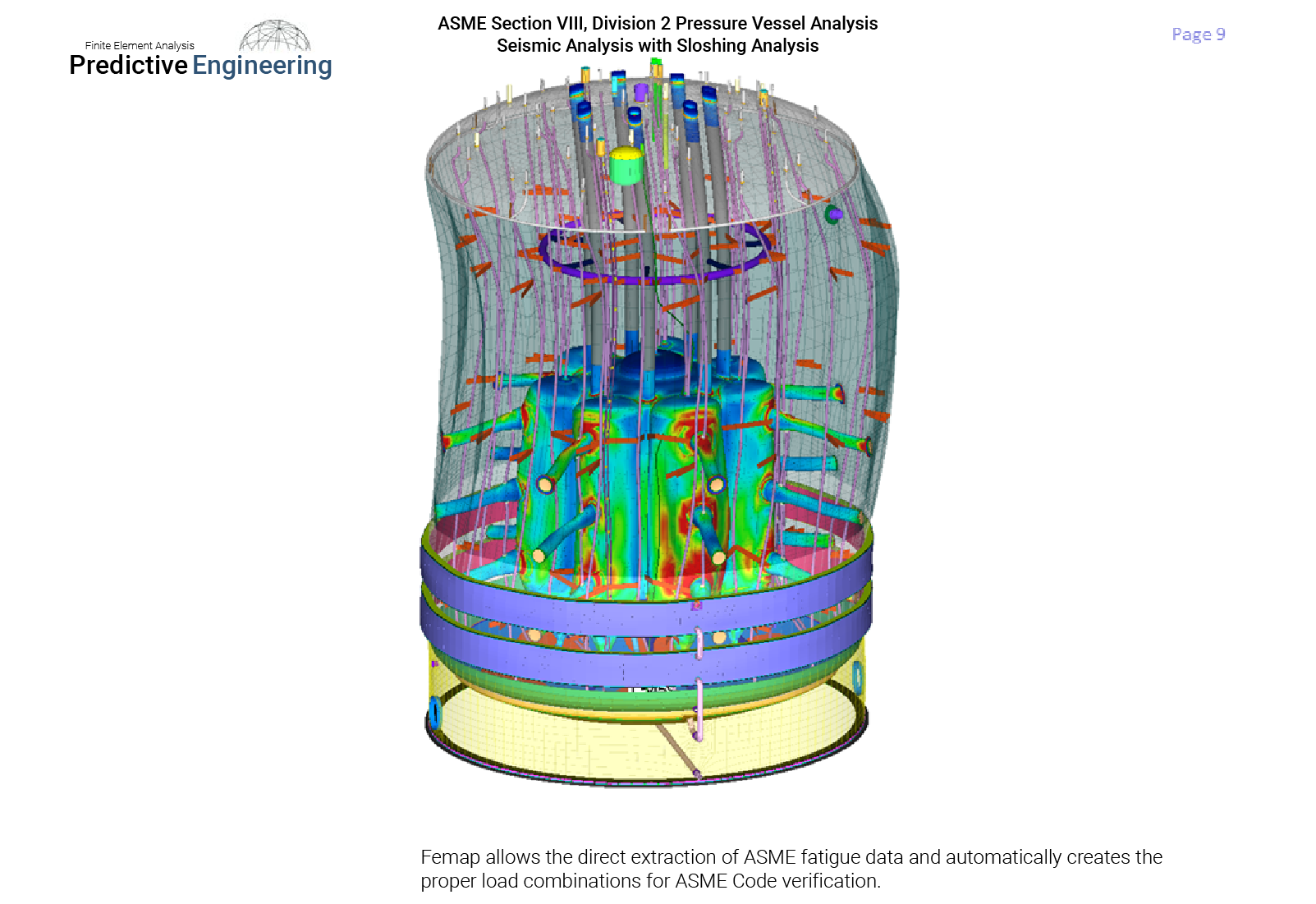

To keep things interesting, the vessels were required to have a 40 year operational lifespan. Thus, after the DBE analysis, a complete fatigue analysis was performed following the ASME Code specifications to carefully determine surface and mid-plane stress intensities at all geometric and weld locations.

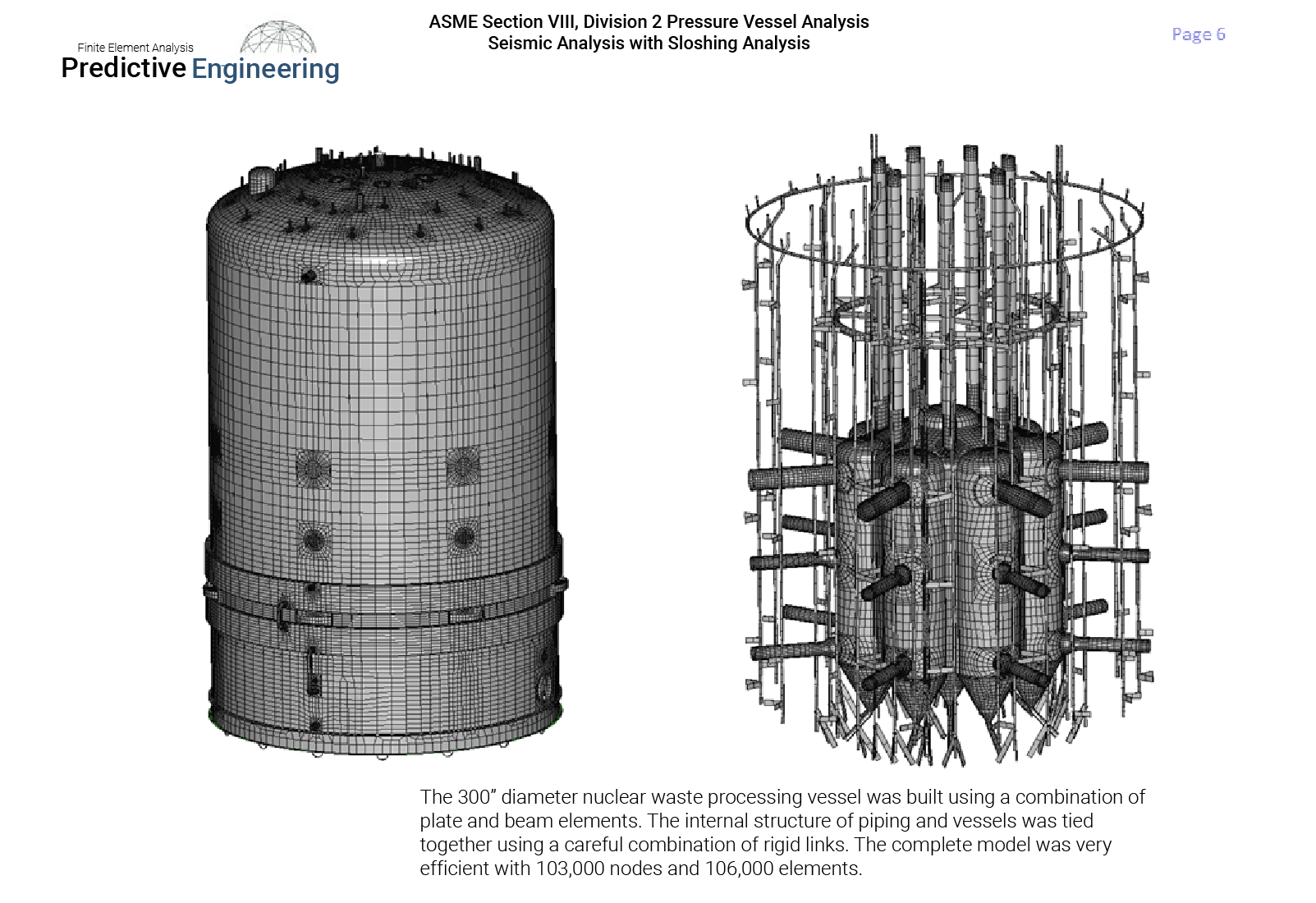

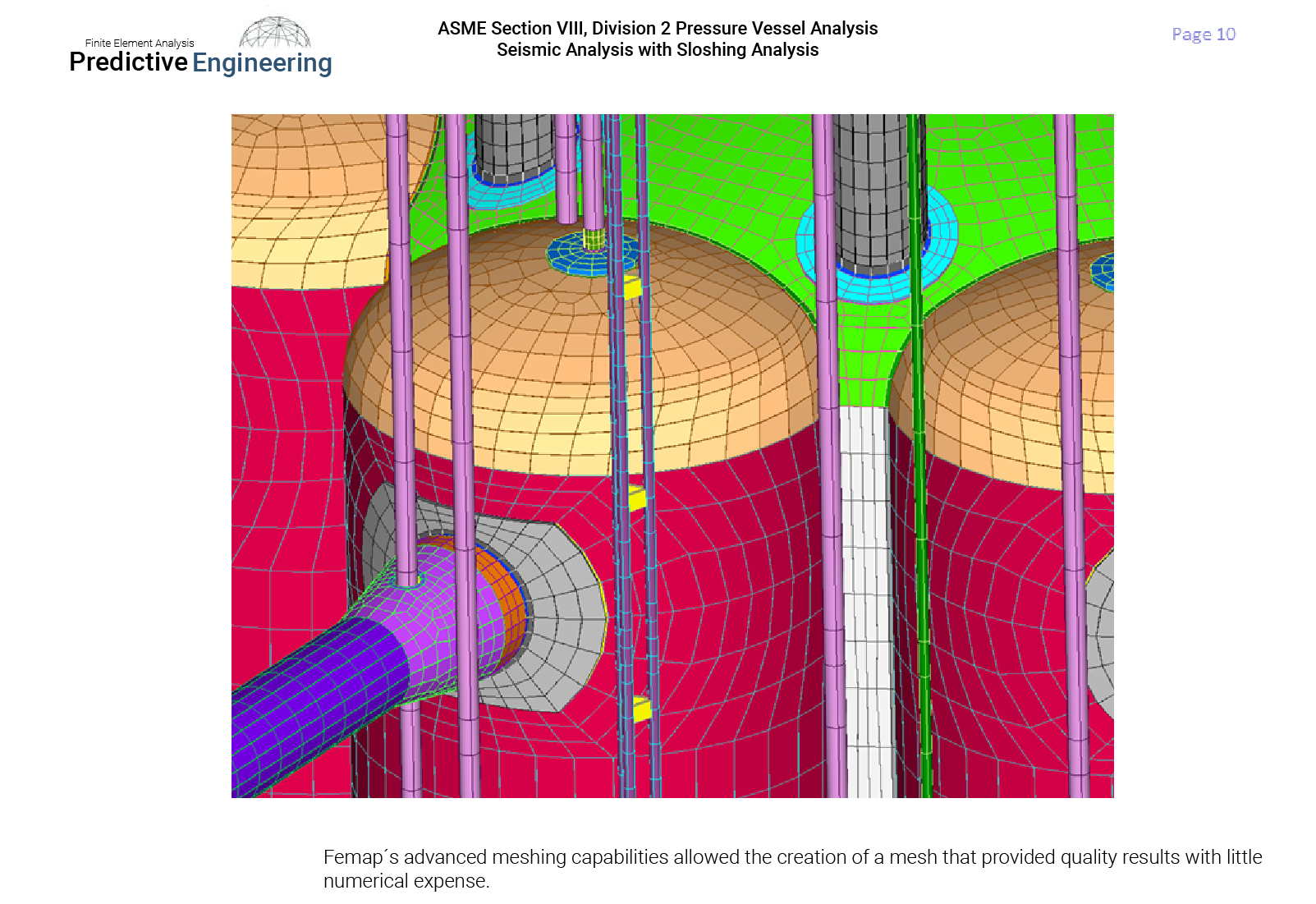

The complete FE model for this project had only 103k nodes and 106k elements which many would consider ridiculously small to capture the complexity of such a vessel. The efficiency of this model was made possible by Femap’s advanced meshing techniques of automatically creating high quality plate elements over curved and non-rectangular surfaces. This compact model was invaluable since the complete analysis set required 52 load cases with extensive intra-load case combinations and created final model sizes in excess of 4 GBytes. With Femap’s 64-bit architecture, model interrogation was quickly done. This was another imperative since the engineering documentation for this project required more than 600 pages.

At the end of the day, it doesn’t matter how nice the model looks or how fast it may solve but rather that the vessel passes and that results can be certified by the reviewing agency. Thus, when the client received formal Nuclear Quality Acceptance (NQA-1) for the complete engineering package covering seismic, fatigue and buckling it was a milestone and a cause for some celebration since it laid the foundation for a complete sequence of other follow-on vessels.

PDF Download