Project Overview

Project Overview

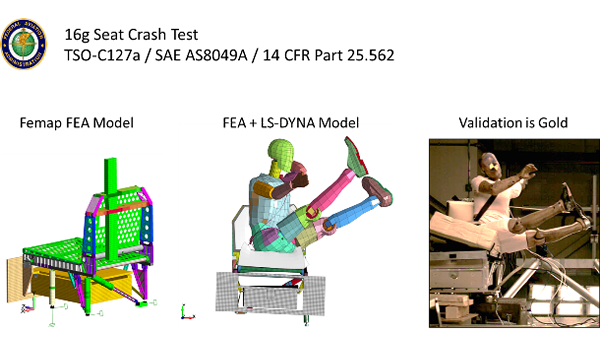

Passing the FAA 16g sled test is no trivial matter for highly optimized aluminum and composite airplane seats. Additionally, getting the anthropomorphic test device (ATD) to behave correctly is also a difficult task in any sled test simulation. The objective of this LS-DYNA simulation was to ensure that the client’s seat could be validated against the 16g test sled results and that subsequent seat versions would pass “the first time”.

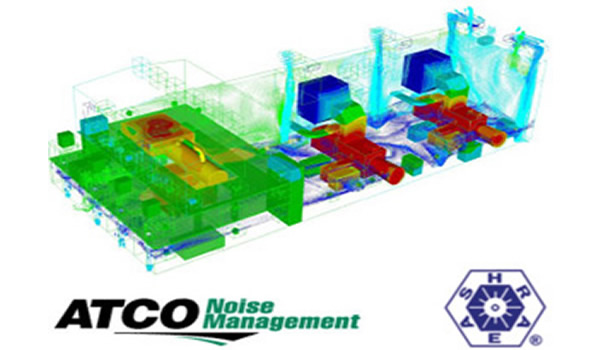

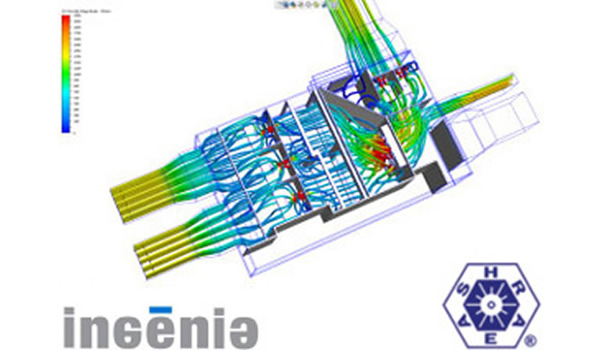

Computational fluid dynamics study on dual, gas turbine co-generation power plant building. The building had strict external noise requirements and thus required that the building remained sealed through out the year. As such, the building was air conditioned via large air movers at the rear and on the roof.

CFD studies allowed the efficient sizing of the air conditioners and provided accurate predictions of temperature profiles within the building.

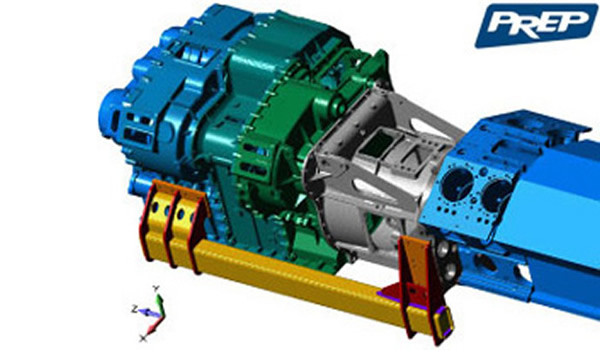

Structural and modal analysis model of a large industrial transmission. The model had 3.2 million nodes and uses a broad array of NX Nastran elements.

The analysis employed bolt preload and full contact between flanges and internal shaft/bearing points.

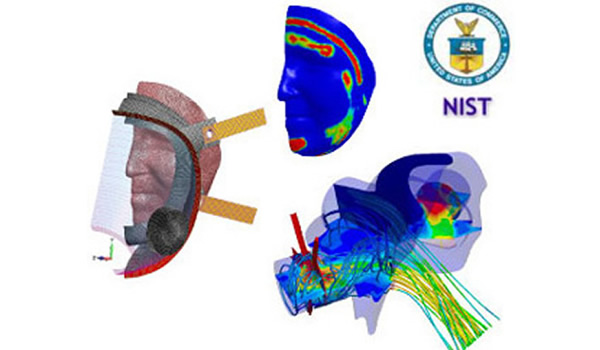

This project simulated the fit and function of a respirator mask. The silicone rubber mask was fitted onto a human head with contact pressures calculated using LS-DYNA. The transient air flow of the breathing pattern was then modeled using CFdesign.

Effort funded by the Department of Homeland Security Science and Technology Directorate.

CFD study was done on a large roof-top mounted air handler system. Stringent flow requirements were imposed by the end-user (a large hospital in Ohio) to ensure that the HEPA filter would perform efficiently. The CFD model contained blowers, multiple filters, heaters, coolers and a complex air mixture. Results indicated that the design would meet all of the design requirements and was accepted by the end user and is in service today.

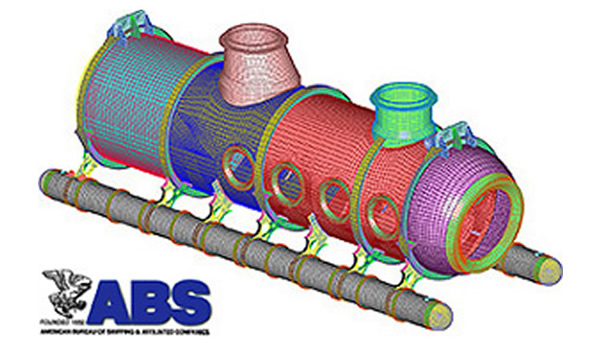

American Bureau of Shipping (ABS) regulations requires that all manned submersibles have a minimum buckling strength of 2.0. The fallacy of this linear, Eulerian buckling approach is that it is typically very conservative and that the true buckling limit for a heavy reinforced structure can be much greater. Current Code agencies (ABS, DNV, API, FVMSS) are not accepting nonlinear buckling analysis as acceptable means to demonstrate buckling compliance.

In recent work on a two-person deep-diving submersible, LS-DYNA was used to calculate the true buckling load limit for the hull. The design of the hull was done using the standard ABS Rules for Building and Classing of Underwater Vehicles, Systems and Hyperbaric Facilities provided an analytical buckling load limit of 2x. The LS-DYNA results showed that the ultimate buckling limit of the hull was around 3.5x the rated dive pressure. An animation of these buckling results is shown in the provided video. This submarine hull has been surveyed by the ABS and accepted. The submarine is currently under going sea trials.

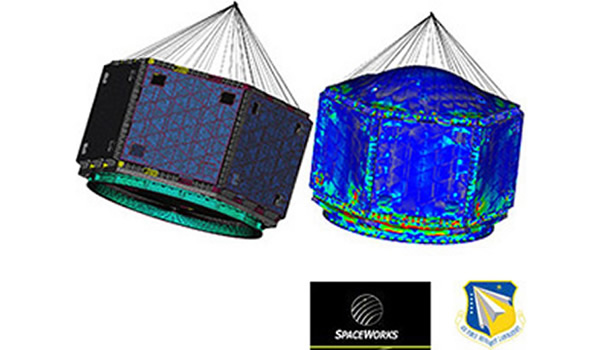

Advanced satellite design for the USAF through sub-contractor Spaceworks. The model was built using Femap and analyzed using NX Nastran. Peak loads are experienced only during launch and this is simulated using a power‐spectral‐density (PSD) normal modes analysis. The model contains nearly 900,000 nodes and correlated within 5% to experimental results. It represented a “first” for the client to execute large models in a timely and accurate manner.

Eight passenger, deep‐diving (depth 1,200’) luxury submarine built with Femap and analyzed using NX Nastran. First human occupancy submersible certified by the American Bureau of Shipping via the finite element method.

View Submarine Impact Simulation (YouTube)

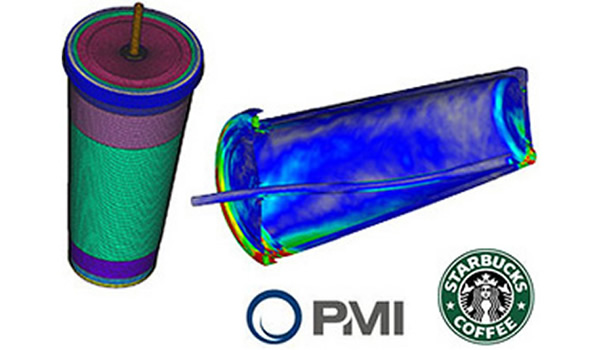

mpact testing of consumer projects is quite common. However, virtual impact testing is just in its infancy for standard consumer products. This model was constructed from Solidworks geometry imported into Femap and then analyzed using LS‐DYNA. Simulation results showed definite regions for improvement and upon testing, the design passed with flying colors and can be found at your local Starbucks coffee shop!

View Coffee Cup Impact Simulation (YouTube)

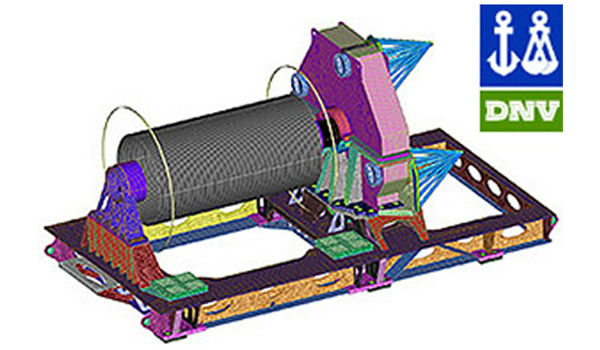

High‐speed, high‐torque, 6,000 HP off‐shore oil drilling winch built with Femap and analyzed using NX Nastran. Passed DNV (Det Norske Veritas) certification with no problems while beating the client’s design weight requirement by 15%.

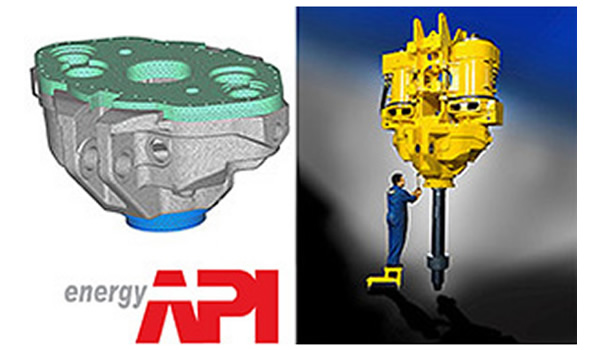

1,100 Ton Top Drive Gearbox for off‐shore oil production modeled using Femap and solved with NX Nastran. The gearbox was certified under the American Petroleum Institute (API) and DNV Specifications. It was the first of its kind to pass complete load testing with no failure.

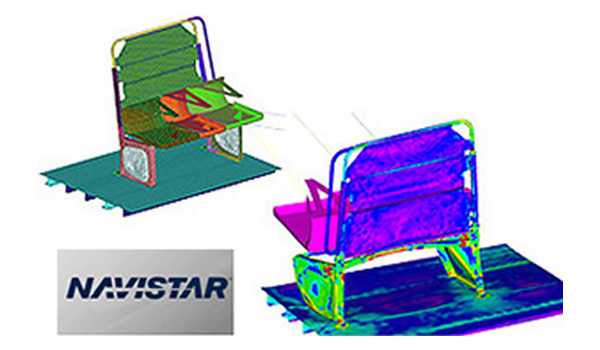

Bus seat analysis with the geometry imported from Unigraphics into Femap and then solved using LS‐DYNA.

The model simulated the Federal Motor Vehicles Safety Standard for seat belt retention during a crash event.

This was a new design for Navistar and incorporated the latest FMVSS requirement for seat belts. Numerical simulating greatly accelerated the testing program and shaved pounds of material off of the seat design.

Our Partners