Fan Characterization and Performance Analysis with CFD

Analysis

Objective

Fans are essential devices that are critical to many functions of modern life. We show how CFD can optimize fans of all shapes and sizes and not be a cartoon (validate to test).

Introduction

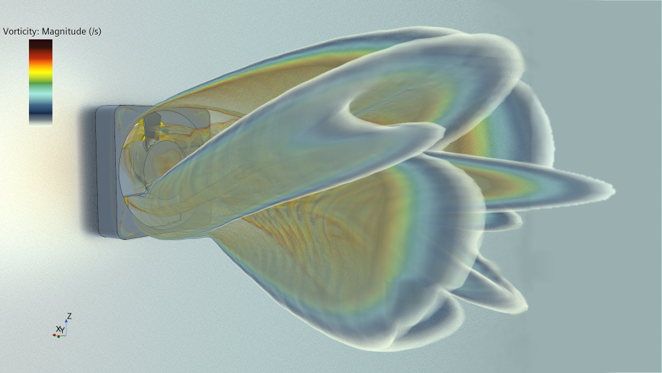

Fans are essential devices that we encounter every day without much thought, but they are critical to modern life. From small devices in your computer laptop to large air movers for building ventilation, you will encounter these items throughout the day. These analyses can be inherently challenging problems that involve transient fluid structure interaction. We are interested in developing a fan characterization curve or determining sources of acoustic noise. At Predictive Engineering, we have years of experience and expertise in the models and methods for CFD fluid and FEA structural analysis of fan and turbine blades.

Build and test has been a traditional method for fan development over the years, and technologies such as 3D printing and rapid prototyping have significantly reduced cost and time. However, there are still limits to the number of design iterations you can evaluate and the amount of information you can obtain. With CFD simulations, we can take advantage of model parameterization and optimization to automate running hundreds of studies and delve deeper into model results. With building and testing, you typically only measure flow and pressure to characterize the fan. With simulation, we can understand everything that is happening in the flow field, from pressure and structural loading on the blades to sources of acoustic noise. These results can be used to inform design decisions and achieve better performing designs.

PDF Download

Fan Characterization and Performance Analysis with CFD

- Moving Reference Frame: The mesh is static throughout the simulation, and the region closest to the fan blade is modeled as a moving reference frame. This imparts angular momentum and velocities to the local cells and surfaces.

- Pros: Steady state method that can be solved relatively quickly and accurately characterize fan performance.

- Cons: Provides a time average solution, so it will not capture oscillating dynamics.

- Rigid Body Motion: The local mesh near the fan blades physically rotates.

- Pros: Can accurately capture the transient dynamics of air flow through the fan blades for aero-acoustics analysis.

- Cons: Transient models can take a significant amount of CPU time to run.

- ·Overset Motion: A "cookie-cutter" method where fan blades are cut out of the background mesh.

- Pros: Can be coupled with fluid structure interaction (FSI) to capture fan blade deflections and increase accuracy.

- Cons: The most computationally intensive of the three methods.

In our first example, we evaluated the performance of a 24-inch diameter fan in STAR-CCM+. This fan was intended for building ventilation applications in agricultural settings. We used the moving reference frame technique to efficiently and accurately estimate the fan performance between set pressure differentials. In addition to fan performance, we extracted blade pressures and resulting loads from the model for structural static FEA analyses.

The client required a custom fan solution to meet the environmental operating conditions for space flight hardware. They based their design on a previous unit and wanted to use CFD to evaluate fan performance in parallel with rapid prototyping and testing. We used the moving reference frame technique to deliver results in a timely manner. The initial results from the CFD analysis showed significant deviations from the targeted performance the client was trying to achieve with their design. At first, this result made us a little nervous about the model and methods, but once the client fabricated and tested their design, we saw that the predicted CFD results matched perfectly with the test results to validate the model. Further evaluation of the CFD model showed that there was potential for unstable flow conditions which could lead to reduced performance. The client adjusted their fan design, guided by the CFD findings, and was able to significantly improve the results on a subsequent test.