Burst Containment: Aviation, Industrial, Medical and Military

Analysis

Objective

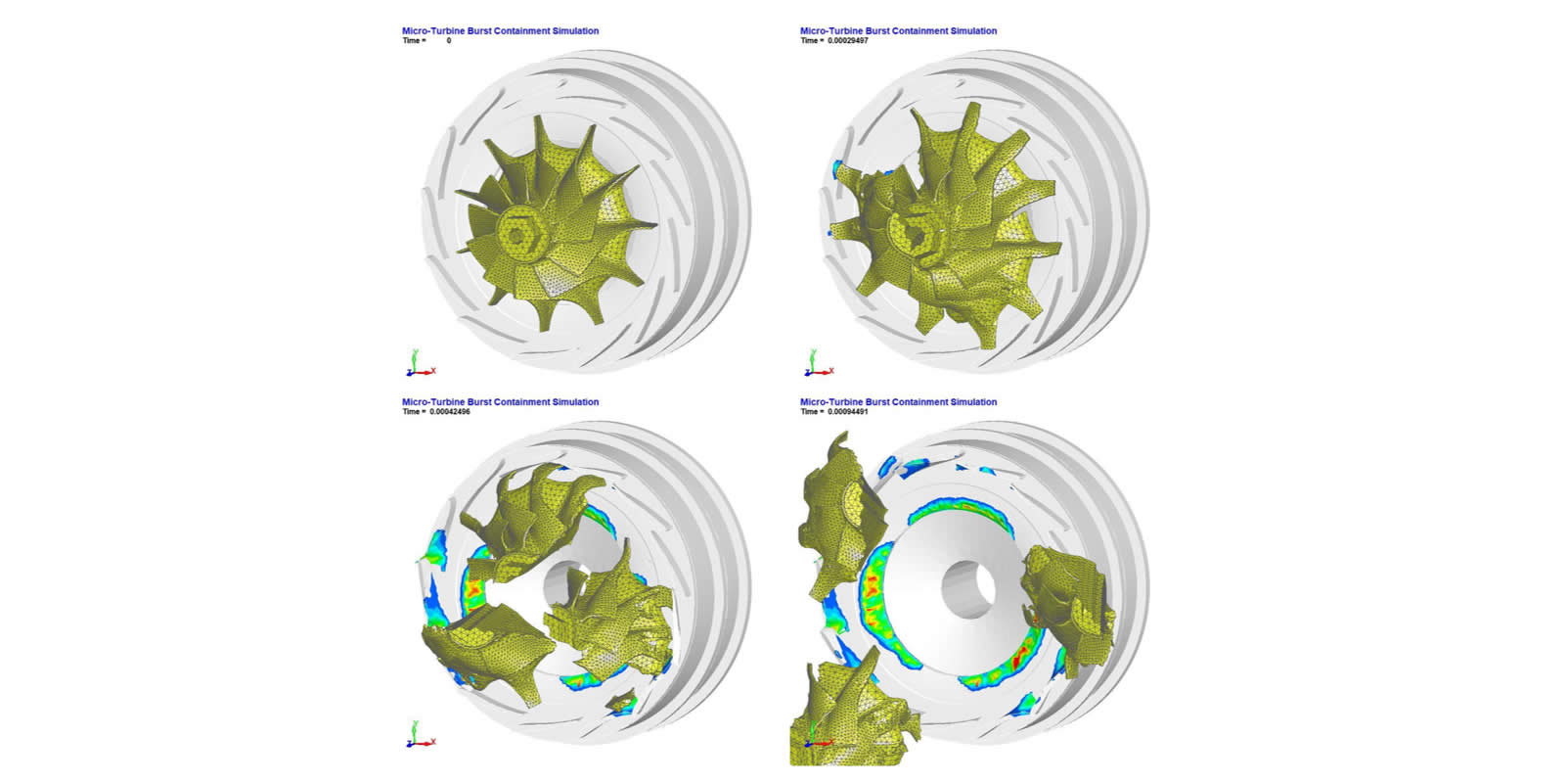

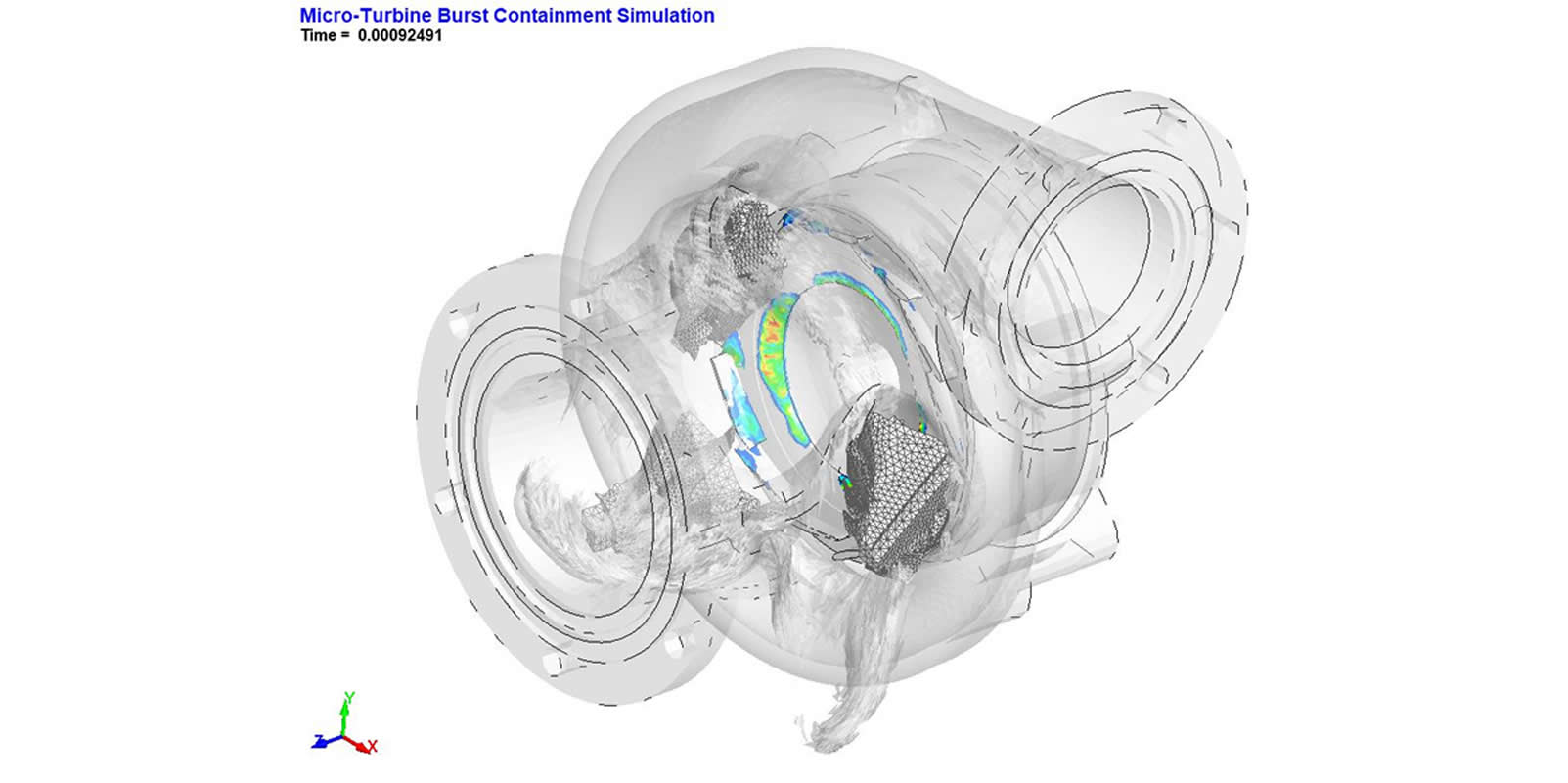

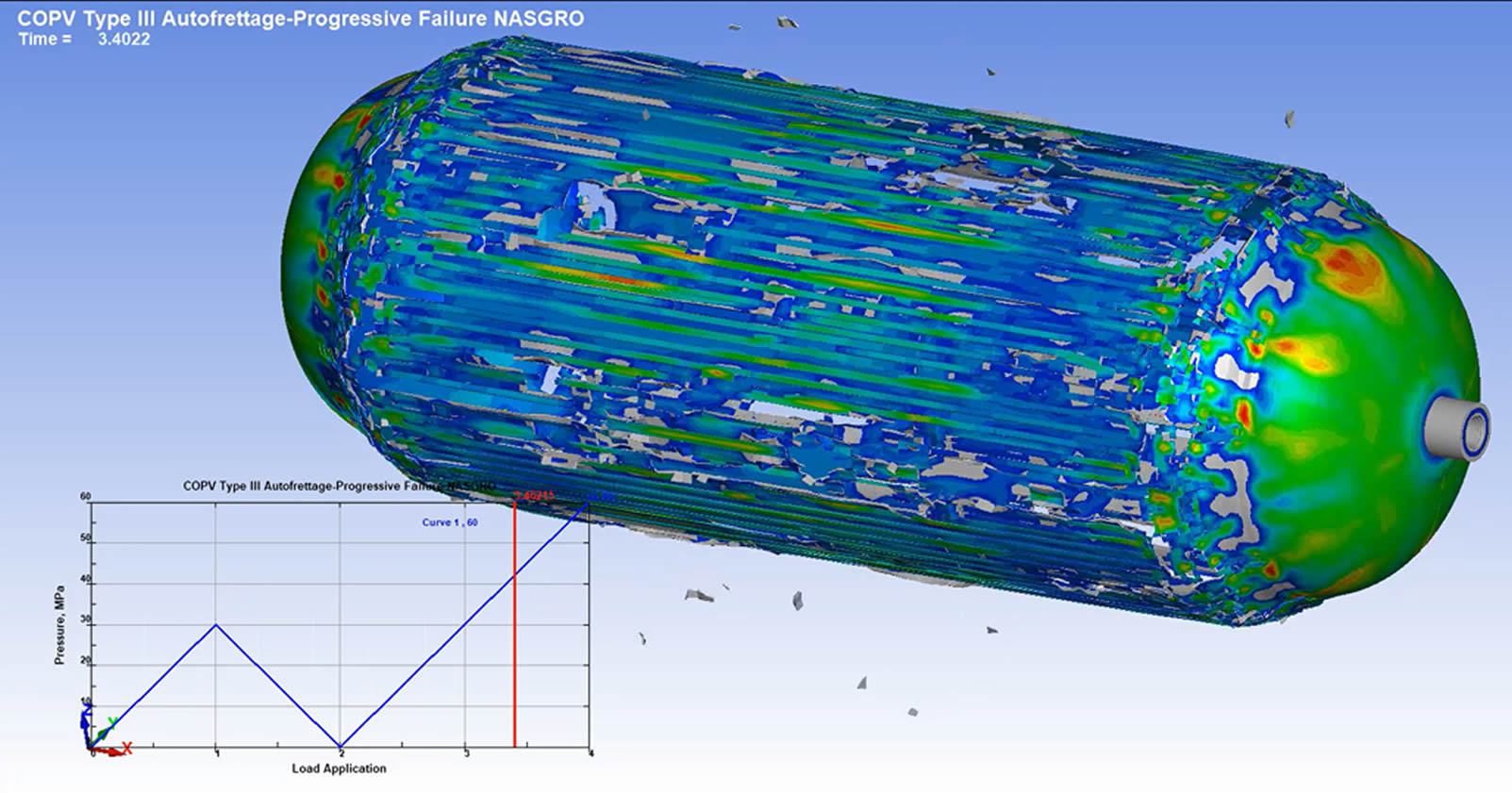

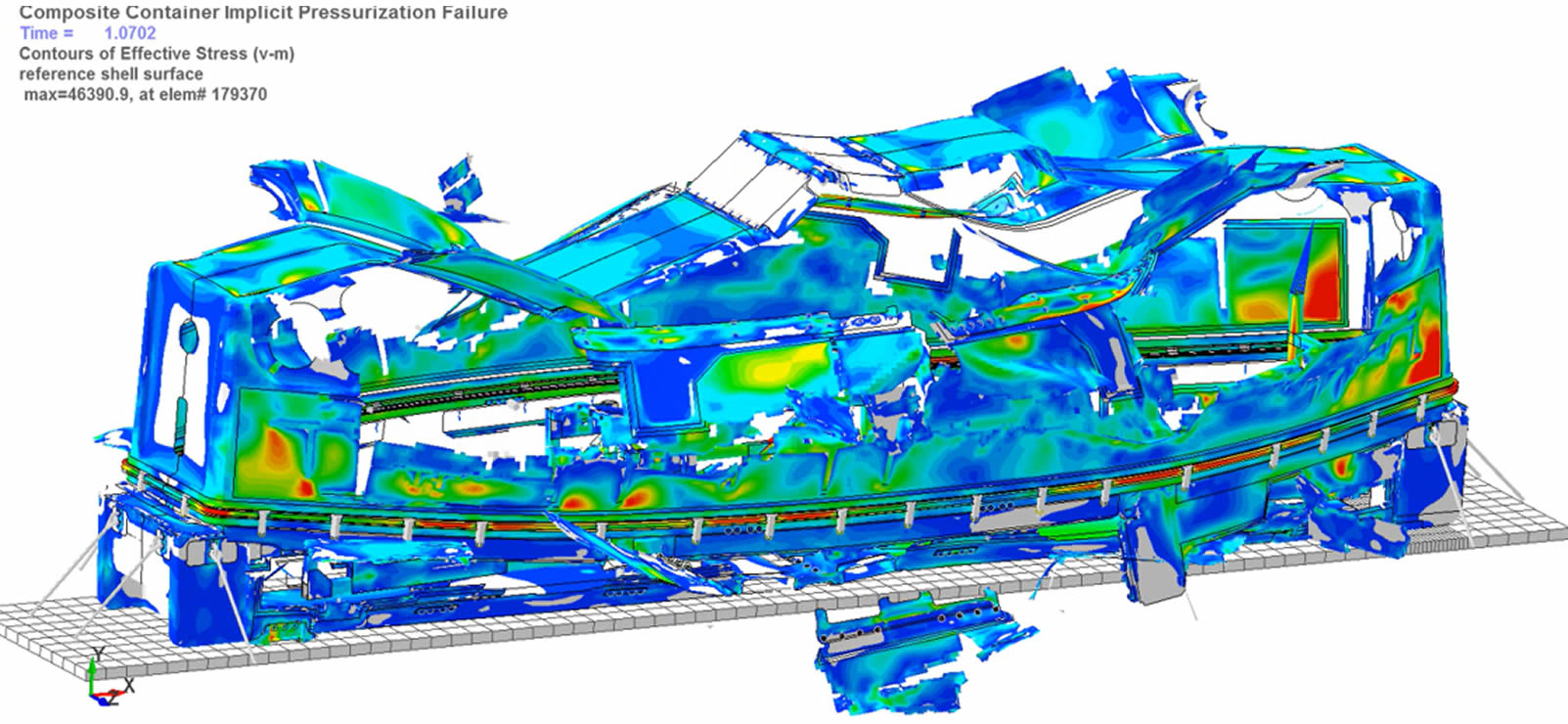

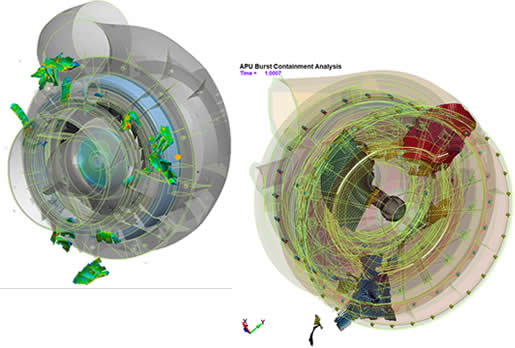

Provide accurate burst containment simulations for high-speed rotating equipment.

Burst containment testing is challenging and expensive since the test destroys pretty much everything and often times, one has no idea if containment or non-containment was marginal or not. The challenge with finite element analysis is determining if the result is a cartoon or a simulation. The engineering software cost for performing a transient, dynamic nonlinear simulation burst containment simulation is minimal but it still requires engineering experience to make it all work accurately. Our nonlinear FEA consultants have decades of validated experience.

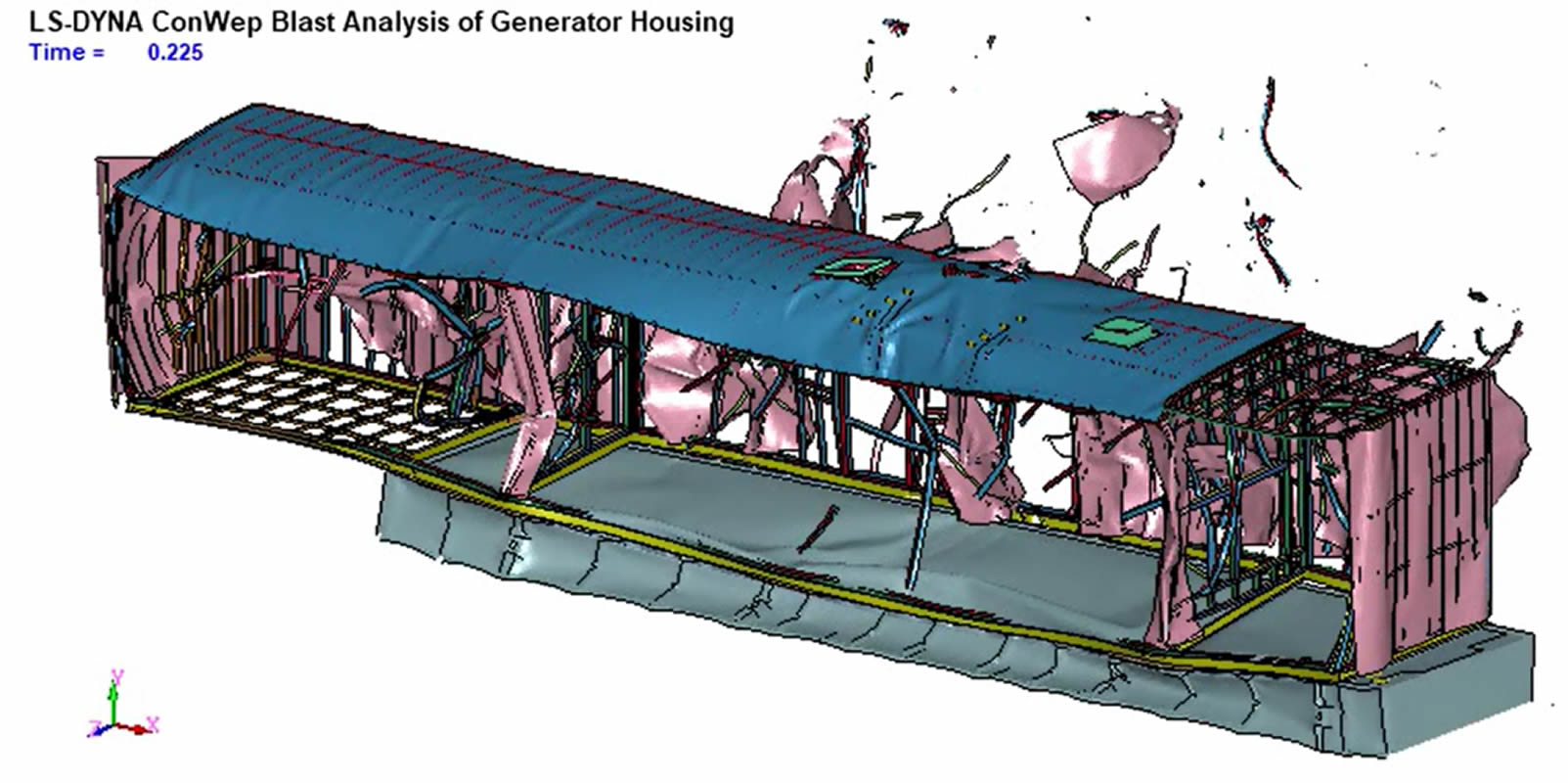

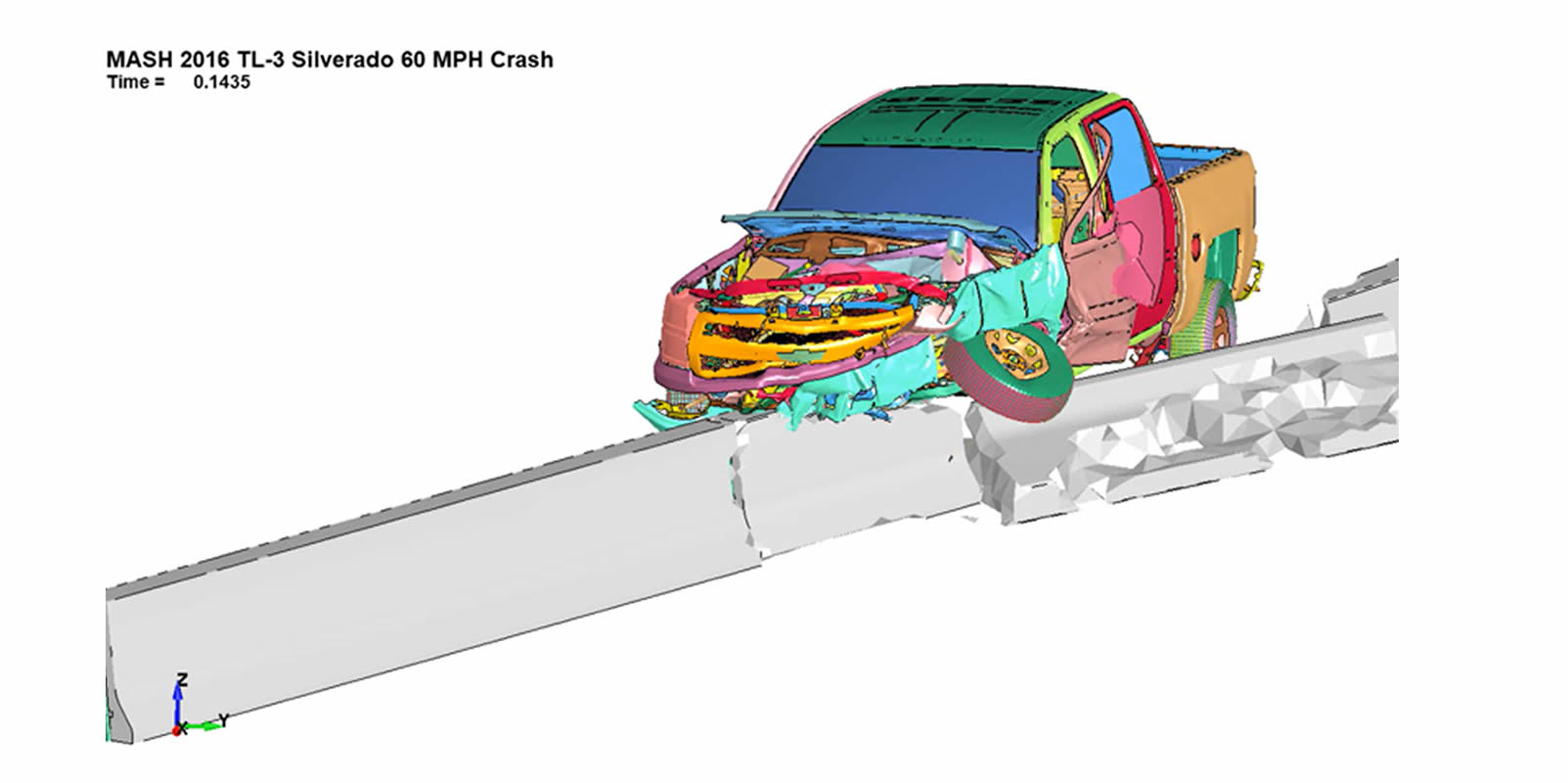

This short note covers our engineering consulting services work on burst containment within four major industries: aviation (auxiliary power units or APU’s), Industrial (electrical power turbines), Medical (x-ray scanning machines) and Military (blast containment). We are pleased to state that our simulation work has been validated and has stood the test of time.

PDF Download

Burst Containment: Aviation, Industrial, Medical and Military